Improved laser drilling boosts aircraft aerodynamics performance

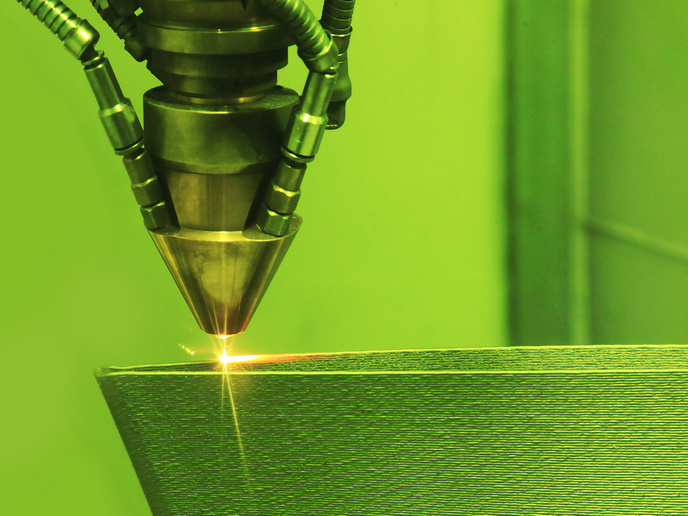

Intense laser pulses a quadrillionth of a second in duration have significant implications for basic scientific research and for practical applications. One of their most important applications is in the manufacture and transformation of metals.

Technology needs to meet productivity

Despite the potential of femtosecond lasers(opens in new window), it is difficult to incorporate them into industrial solutions that require processing large surfaces, volumes or a large number of parts. Six European companies have joined forces in the EU-funded MULTIPOINT(opens in new window) project with one goal in mind: to develop a femtosecond laser system that balances the precision-productivity trade-off in industrial manufacturing processes. “Ultrashort pulse lasers are noted for their ability to precisely machine materials and structures with minimal thermal damage. However, this extraordinary precision comes at the expense of productivity,” notes project coordinator Roberto Ocaña. To increase productivity while maintaining precision, researchers employed two strategies. The first one involved building ultrashort pulse lasers with higher average powers. The second one consisted of developing a multibeam generation optical unit that divides that main laser beam into several. In this way, a multitool was created that maximises the quantity of the material processed. In addition, the laser system incorporates a control system that assures quality at every stage of the manufacturing process. “The technologies to build such a laser system are available, but their materialisation is not simple at all,” explains Ocaña.

Hole drilling in aircraft structures undergoes a sweeping revolution

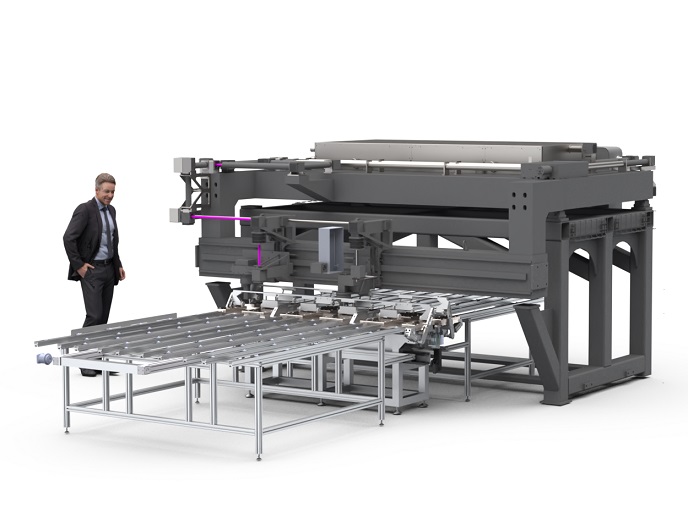

“We developed a laser that delivers an average power of 700 W, much higher than that of commercial lasers. The pulse repetition rate ranges from 300 to 700 kHz, corresponding to pulse energy from 0.97 to 2.27 mJ, respectively,” reports Ocaña. One of the future applications of this femtosecond laser system is high-productivity micro-drilling. “There is a growing demand for successful machining with small tools. Micro-drilling is critical for the production of microfilters, hydrogen electrolysers, acoustic panels and hybrid laminar flow control (HLFC) panels,” notes Ocaña. MULTIPOINT focused on the perforation of large-dimension titanium panels. The technology called HLFC has proved to improve fuel consumption in commercial aircraft by up to 10 %. HLFC panels mounted on wings or tail stabilisers offer a way to reduce frictional drag through sucking the air through small holes. “Currently, there are no prototype femtosecond lasers capable of micromachining large-size sheets. Current femtosecond lasers can process smaller areas, have much lower average powers and have simple beam delivery systems. A high-power femtosecond laser system capable of processing with a multibeam system in an area of approximately 2x2 m2 is unique in the world,” notes Ocaña. There are other laser drilling techniques alternative to femtosecond lasers for skin perforation, which can achieve a high throughput of around 300 holes per second. However, these laser techniques produce burrs and splashes of molten material around the hole perimeter that must then be removed by etching and polishing. “The MULTIPOINT laser is expected to minimise post-processing steps and increase the quality of the micro-drilling process while maintaining reasonable productivity levels,” underlines Ocaña.

The prominent role of EU funding

Researchers and companies often struggle to lift their ideas off the ground although the knowledge is there. “Bringing an idea to fruition involves the participation of a large number of companies and researchers working in different fields. EU funding greatly supported us on this. Having tools that allowed us to test advanced photonic technologies is crucial for cementing EU’s leading position in the field worldwide,” Ocaña concludes.