Self-healing, recyclable thermosets offer a greener alternative to single-use plastics

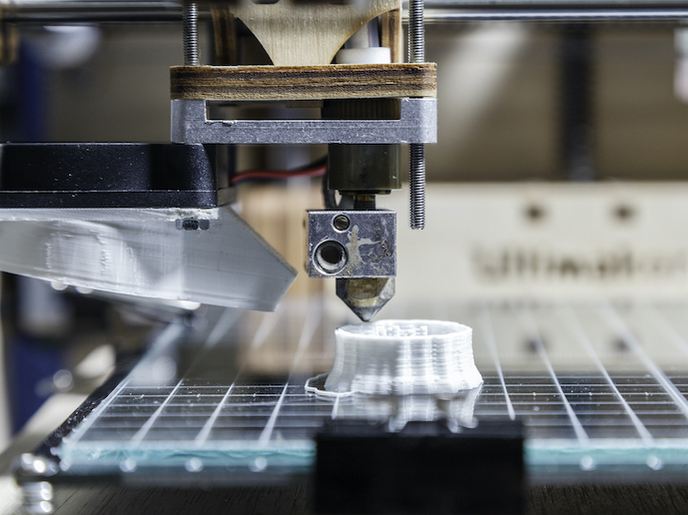

As environmental concerns and depletion of fossil-based resources increase, the development of sustainable resins derived from bio-based molecules is gaining momentum in the 3D-printing industry. Traditional thermosets, which are difficult to melt down and reprocess, pose a significant challenge when it comes to their end-of-life disposal. Funded by the Marie Skłodowska-Curie Actions programme, the SUSTAINABLE project proposed strategies to harmonise the favourable properties of thermosets with their ability to be mechanically and chemically recycled. These included the use of dynamic covalent cross-links. “Containing reversible cross-links, resins can be reused in new forms without losing their beneficial properties,” notes project coordinator Minna Hakkarainen. “Moreover, these resins can be hardened or ‘cured’ using a low-energy process at room temperature, making them easy to work with. They can also be shaped into various structures using digital light processing(opens in new window) (DLP).”

From wood molecules to a robust 3D product

The project team, consisting of individual MSCA postdoctoral fellow Dr Anna Liguori and Prof. Hakkarainen, synthesised a wide library of bio-based resins derived from wood molecules – vanillin, eugenol and isosorbide. These resins were modified with photocurable groups, which allowed them to harden under light exposure. “The goal was to create self-healing and recyclable thermosets that retain their shape after heat treatment,” states Hakkarainen. “To achieve this, the resin structures included dynamic covalent linkages that can be opened and reformed under specific stimuli. Schiff-base(opens in new window) (also known as imine linkage) and ester(opens in new window) bonds were used.” Taking a vanillin-based resin as an example, the team used an ultraviolet lamp to harden it, resulting in a thermoset material resistant to most common solvents. The material also demonstrated good thermal stability, remaining stable at temperatures above 300 °C. The cross-linked structure and imine linkages endowed the thermoset with a unique combination of malleability, self-healing properties and the ability to be reprocessed thermally. Furthermore, the thermoset could be chemically recycled by immersing it in ethylenediamine, which triggered a process called transimination. The result was an oligomeric product with amine-terminal groups, which can be used to make new thermoset films. The team also demonstrated that this resin can be used to produce 3D objects using DLP. This resin was further enhanced by dispersing cellulose-derived carbon dots in it, which self-assembled into microfibres when exposed to DLP. Compared to the original vanillin Schiff-base thermoset, this composite showed lower transition temperature and inferior shape memory properties. However, it demonstrated better mechanical and chemical recyclability.

Alternative curing methods

In another study, researchers investigated an atmospheric plasma post-treatment method for coating 3D printed structures. Compared to ultraviolet-light treatment, this method increased the surface hydrophilicity of vanillin-derived thermosets, improving the coating uniformity. This treatment also enhanced the ultraviolet shielding and antioxidant properties of the coated thermosets.

Isosorbide-based resins under study

Four isosorbide-based resins were developed for 3D printing, with their composition directly affecting printability and the resulting thermoset’s properties. While methacrylated isosorbide added rigidity, it negatively affected printing quality and solvent resistance. Increasing methacrylated vanillin concentration improved these issues but reduced thermal stability. Using methacrylated Schiff-base resin instead decreased rigidity but improved solvent resistance. With dynamic covalent bonds, the ester-imine thermosets retained their elastic modulus after recycling. “The sustainable production and recycling of innovative bio-based thermosets has hitherto received poor attention. Most studies favour thermal curing methods over the more efficient, eco-friendly light-driven ones. Furthermore, a novel plasma-assisted method enables easy coating of 3D-printed thermosets, broadening their applications in areas where surface properties are vital,” concludes Liguori and Hakkarainen.