Robots carry out aircraft inspection

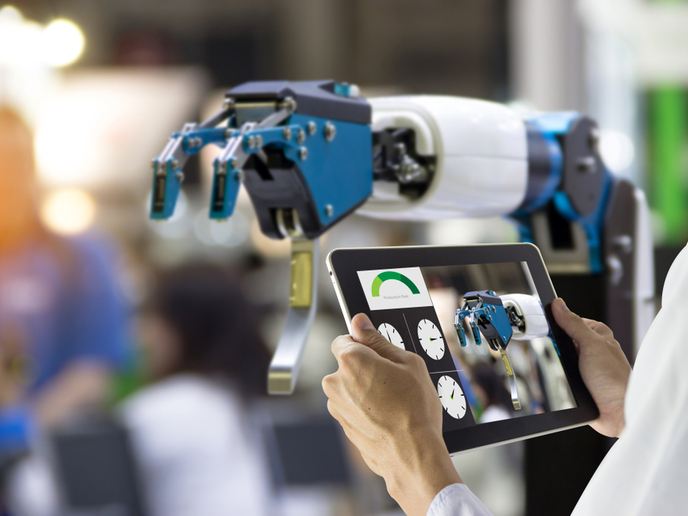

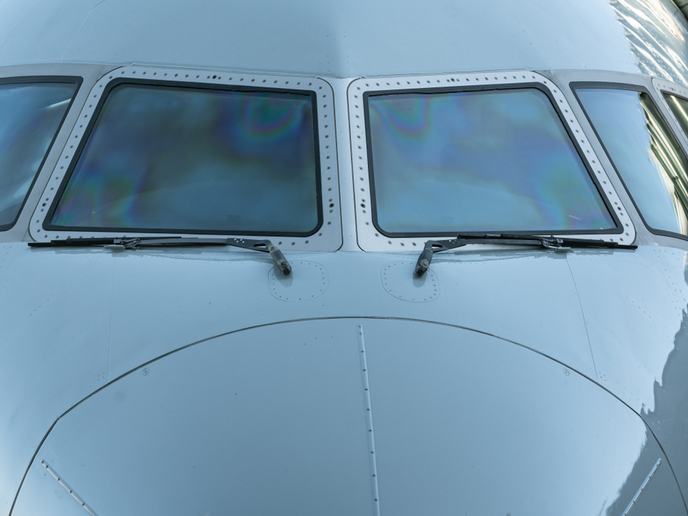

Manual inspection of aircraft is both time-consuming and expensive and also vulnerable to human error. The process is particularly costly when components need to be examined by X-ray as they must first be removed from the plane. The Robair project has solved the problem by developing a robot inspector that can conduct mandatory non-destructive testing (NDT) of civil aircraft. Researchers developed a device that can climb over an aircraft’s fuselage and wings while searching for loose rivets and cracks. The device enables data to be automatically collected and checked and structural flaws identified without having to first remove components. The robot employed both conventional sensors and state-of-the-art technologies developed by the project. Flexible feet adhere to the curved surface of the aircraft and sensors check that there is sufficient vacuum to hold the robot in place before each step is taken. A series of universal joints in each foot, ankle and the rest of the structure provide sufficient flexibility to enable it to climb over the aircraft. The prototype and technologies developed by the Robair project will be commercialised following the project’s completion. The work undertaken by the consortium will help promote Europe’s aviation industry in the global marketplace.