New nano materials for nano machines

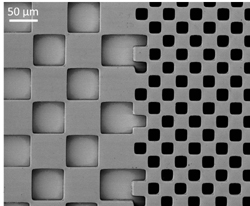

The 'Academia and company collaboration and technology transfer in advanced polymers' (Acapoly) project is working to develop a new set of materials for micro/nano electro-mechanical systems (MEMS/NEMS) technologies. The polymer materials under development are Ormocer and SU-8, and the objective is to modify them so they can be processed using electron beam lithography, direct laser writing (DWL), UV-nano imprint lithography (UV-NIL) and ink-jet printing (IJP). The materials and process libraries will be used for making UV-NIL stamps, light-emitting diodes for automobiles and large arrays of optical waveguides. Classified according to various properties, including that of geometrical shape, optical waveguides are structures that guide electromagnetic waves in an optical spectrum. In the first 24 months of the project, Acapoly concentrated activities on preparing materials and structuring the necessary technology. To develop epoxy-based resists that DWL can pattern, the resists had to be modified and optimised. Also, researchers prepared and lithographically investigated three generations of DWL materials sensitive at wavelengths over 400\;nm. The Acapoly researchers successfully patterned test structures for epoxy resin-based resists. The resulting materials will be studied for potential development as a commercial product. In efforts to develop and characterise suitable materials to be used for manufacturing microlenses with an IJP tool, Acapoly modified standard polymers by adding commercially available materials with known chemical, mechanical and optical properties. Other work in this area has led to the development of two more materials, InkEpo and InkOrmo, based on epoxy resins and Ormocers. These were successfully tested by IJP at room temperature. Project partners have used secondary electron microscopy, light microscopy and white light interferometry to determine the geometrical shapes of lenses and material constants. Results have made it possible to investigate the first series of microlens arrays for optical properties and reproducibility. Future work will concentrate on optimising selected inks and categorising chemical, physical and optical properties of IJP microlens arrays. The Acapoly team will also work towards making other micro-optical components such as astigmatic microlenses.