Advancing knowledge of multifunctional materials use

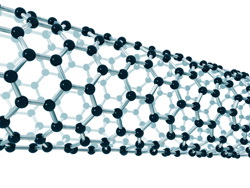

The 'Size effects in mechanical properties' (Nanomeso) project aimed to advance the frontiers of knowledge in multifunctional materials science and nano-micromechanics by narrowing the gap between current theories and experimentally observed size effects. Nanomeso took an integrated approach involving computational models (simulations) and experimental measurements. This was expected to enable the development and validation of a computational tool for understanding and predicting unique plasticity phenomena. The simulation work and advances achieved by project partners generated knowledge that overcomes at least one limitation in work on simulations of nanocrystalline materials. Results can influence future work on the design of computational tools for constructing atomistic nanocrystalline samples and investigations of dislocation-mediated plasticity. This makes it easier to predict where dislocation will take place during deformation. Other project results enable a systematic analysis to be performed for extracting important information needed to develop essential empirical laws to be applied in practice. Nanomeso work emphasises that the studying of fundamental atomic processes contributing to interface-dominated plasticity can provide much valuable knowledge. Developments open the way to conducting more reliable discrete dislocation dynamics (DDD) simulations where microstructures can be realistically treated. Successes in this area of study help overcome barriers usually prohibiting the use of novel materials or components due to inadequate knowledge. Project outcomes have the potential to support long-term innovation important for industrial applications of multifunctional metallic components.