Nano-structured polymers with enhanced properties

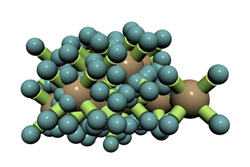

Polymer nanocomposites are polymer matrices reinforced or filled with embedded nanoparticles. Nanoparticles, or particles the size of atoms and molecules, demonstrate a tremendous increase in the ratio between surface area and volume compared to larger particles. The increased interface with other particles in the local matrix environment produces improved chemical and physical properties of polymer nanocomposites compared to conventionally filled polymers. Most current nanocomposites achieve primarily physical bonding between matrix and filler. European researchers supported by funding of the ‘Designed nanostructured hybrid polymers: Polymerisation catalysis and tecton assembly’ (Nanohybrid) project sought to facilitate chemical bonding in addition to physical bonding in new melt-processable nanophase-separated hybrid materials to enable a breakthrough in material properties while being compatible with the most common method of shaping polymers. In particular, researchers focused on the use of low-cost olefins derived from the petrochemical industry as feedstock and the development of novel metal catalysts to produce new co-polymers and polymer composites. The Nanohybrid team successfully created novel nanoparticles and synthesised new metal catalyst systems. Production of novel polymer architectures with improved chemical and physical bonding between matrix and filler as well as enhanced nanofiller dispersion was achieved as a result. In addition, the Nanohybrid nanocomposites demonstrated enhanced mechanical properties as well as increased electrical conductivity. Among the numerous applications of Nanohybrid nanocomposites are materials for automotive parts, communication technologies, micro-electro-mechanical systems (MEMS) and textile fibres.