Etching security codes inside perfume bottles

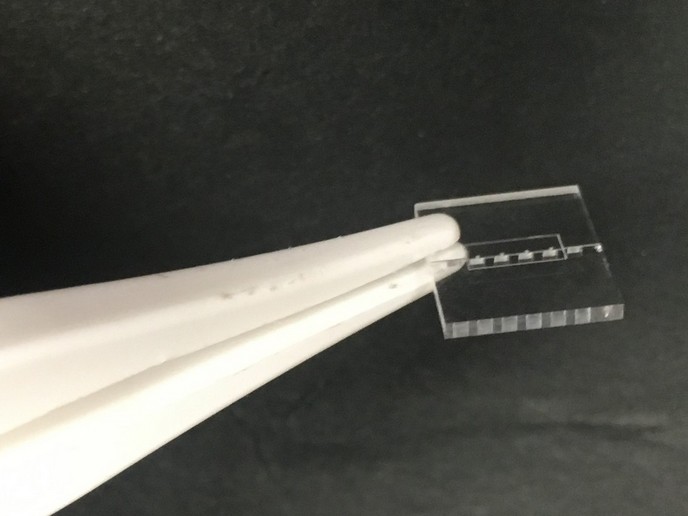

Until recently, the glass engraving market was centred on lead crystal decoration using cutting, grinding and sand blasting. The advent of lasers opened up not only new opportunities for glass etching of decorative pieces but also for engraving special security codes in bottles used for perfumes or pharmaceuticals to fight fraud and counterfeiting. However, laser technologies were not able to adequately handle laser-marking of transparent materials on an industrial scale. A consortium of small and medium-sized enterprises (SMEs) in the field found promising preliminary data regarding technical performance of a high-frequency, short-pulse duration laser but experienced difficulties related to repeatability, speed and price. European researchers responded with the goal of validating the new engraving process with funding of the ‘Non aggressive internal engraving laser system’ (Naginels) project. The over-riding goals of the project were to validate the system’s ability to generate stable, non-degenerating security codes for anti-fraud and normative marking, to generate novel decorations quickly (e.g. one bottle in five seconds) and to provide SMEs with full system cost information. Among the many technical objectives achieved with the new internal engraving process were stability, high accuracy and quality, and negligible cracking or breaking of samples (non-aggressive in nature due to higher laser speeds and less heating). Naginels researchers developed a prototype consisting of a laser for engraving and a vision system for marking verification. The latter provides immediate feedback on readability of an engraved code and excellent quality control. The entire system should help fight fraud while at the same time reducing environmental impact due to absence of harmful chemicals and greater accuracy leading to less scrap. It has been welcomed by industry and the media with much attention and praise and commercial availability is eagerly awaited.