In-line testing for printed circuit boards

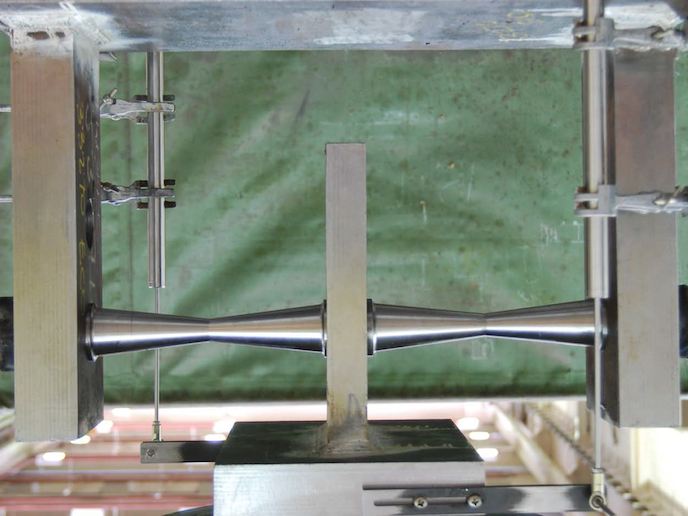

PCBs are the substrates (typically insulating) onto which conductive strips are printed to connect electronic components. They are ubiquitous, found in all kinds of devices from wrist watches and microwave ovens to automotive, aerospace and medical electronics. Defects are common and failure during use can induce major costs to manufacturers as well as damage corporate reputations. Better and faster defect detection during production could lead to tremendous time and cost savings. PCB manufacturers employ a variety of non-destructive testing (NDT) techniques to evaluate products for defects. Most are employed offline and individually. When a defect is found, often the whole batch is scrapped or additional time and expense must be allocated to do further testing of the batch. Limitations in NDT equipment and techniques prohibit incorporation into a single on-line system that would greatly enhance the quality control process. European researchers initiated the ‘Development of comprehensive in-line quality control system for printed circuit board assemblies’ (Microscan) project to overcome current limitations and develop new NDT techniques. They set out to combine the NDT with a PCB assembly system to provide a complete and comprehensive on-line NDT quality control system for PCBs. Scientists integrated four different NDT modules covering X-ray, thermal, (automated) optical and acoustic inspection, each testing for a specific type of defect. The system was incorporated in a generic platform to enable use of individual modules in isolation or in various combinations to best suit manufacturers’ needs. Not only does the system allow on-line detection of all fault types on PCBs for the first time but the prototype was able to detect a number of defects currently not detectable. With increasing complexity of PCBs combined with demand for faster turnaround times from order to delivery, commercialisation of Microscan technology should be welcomed by the electronics industries. Microscan systems have the potential to greatly enhance reliability and quality of PCBs while reducing costs of defect diagnosis, repair and production downtime, not to mention damage to a company’s reputation.