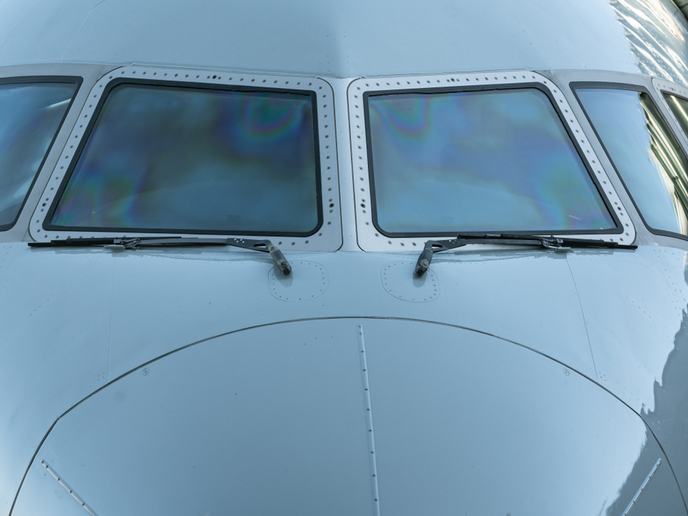

Improved aircraft wing design

High-lift devices maximise the lift of aircraft, dependent in a complex way on wing shape, angle and speed of flight. As engines continue to become more powerful and aircraft loads and speed increase, high-lift devices have become a necessity for keeping take-off and landing within reasonable speed limits. High-lift systems also play a critical role in overall flight performance. Small changes in lift and drag facilitated by such systems can yield major increases in payload capabilities. The aerodynamic design of high-lift systems has become an integral part of aircraft design. European scientists aiming to improve the process initiated the 'Design, simulation and flight Reynolds number testing for advanced high-lift solutions' (Desireh) project. The EU-funded consortium consists of six industry partners, seven research establishments, three universities, two small and medium-sized enterprises (SMEs) and the European Transonic Windtunnel (ETW). Together, the partners are developing numerical tools and experimental measurement techniques for very cold (cryogenic) conditions to enhance the industrial design of laminar wings for high-lift capability. In particular, scientists are working toward development of a high-lift system for the future generation Natural Laminar Flow (NLF) High Aspect Ratio Low Sweep (HARLS) wing that has an optimal wing shape for maintaining laminar flow and thus reducing drag. Scientists have developed algorithms to optimise all phases of flight (take-off, cruising and landing) simultaneously rather than individually, an important step toward a more balanced design process. In addition, they are accelerating the numerical simulation process that will significantly decrease design time given the huge computational load of the complex models. An optimal high-lift wing design has been selected for optimisation and testing. Finally, improvements in the particle image velocimetry (PIV) technique used to measure air flow have been achieved and measurement techniques have been verified for use without modification in wind tunnel tests. The last project phase will be devoted to final optimisations of numerical algorithms and wing design and subsequent wind tunnel testing. Desireh accomplishments are expected to have an important impact on the aircraft design sector by decreasing industrial development costs and time-to-market while enhancing laminar wing performance.