'Smart' clothing to protect against radiation exposure

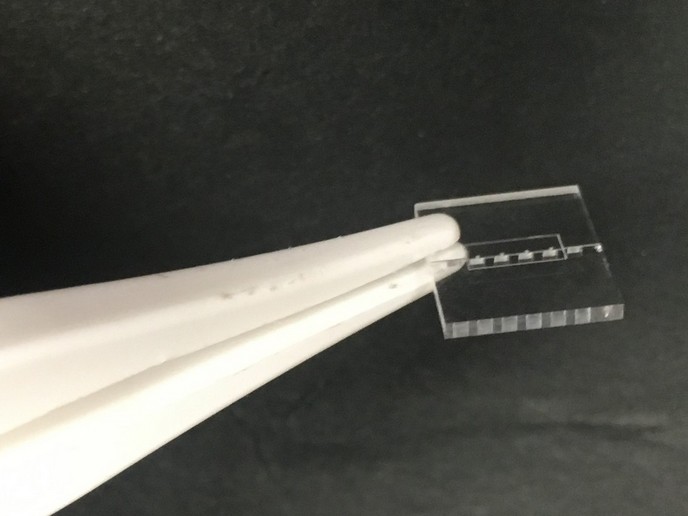

Laser technology is extensively used for material processing as part of automated production systems. Under standard working conditions, these systems are typically closed, providing adequate safety due to housing and safety interlock circuits that switch off the laser source automatically upon opening the housing. However, e.g. during system maintenance, service personnel may have to bridge the safety interlocks thereby exposing themselves to a notable risk of injury by accidental laser irradiation. Similarly, hand-held laser processing devices represent another radiation exposure source. Up to now, this exposure problem is regulated in detail only for the operators’ eyes, but not for the skin. Given the serious damaging potential of radiation to human tissues, urgent protective measures are required to minimise such exposure risks. Based on this, the key objective of the EU-funded PROSYS-LASER was to develop novel laser-protective clothing and curtains for use with hand-held laser processing devices and with non-closed automated laser machines. To achieve this aim, partners generated passive functional multi-layer technical textiles providing high laser resistance and active textiles that capable of deactivating the laser beam. Prototypes for passive and active gloves, jackets and aprons, as well as for active curtains were manufactured. When designing these textiles, researchers had to consider various aspects including their wear resistance, inflammability and washability. Using different mathematical models, partners were able to calculate the time required for the onset of a second degree burn following irradiation exposure. Combined with negligible transmissibility and minimised heat flow, this criterion was used by partners to design the laser protective textiles. For passive textile systems, partners generated multi-layer textiles where the outer layer served as highly remitting material, thus minimising the energy input into the textile system. The middle layer functioned to dissipate the part of the energy that gets absorbed from the outer layer. The inner layer served as an additional barrier for energy transfer to the skin while maintaining low heat conductivity in order to enable perceptibility. Active protective systems incorporated sensors in their middle functional layer offering the additional feature of deactivating the laser beam automatically in case of a radiation accident. Part of the PROSYS-LASER work included the development of a procedure to test the protective systems in particular in terms of heat flow to the skin due to radiation absorbance as well as of radiation reflectance and transmittance. The laser protective textile innovations developed during the PROSYS-LASER initiative have great commercial exploitation potential. Most importantly, these novel materials could significantly improve employee safety by reducing occupational injuries.