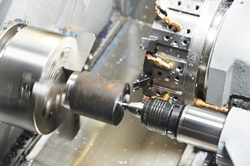

All-in-one generic metal machining systems

Innovative materials such as titanium alloys and various composites form the basis of lighter and more complex components. These properties make them attractive to industries such as the automotive and electronics sectors but are a thorn in the side of manufacturers given their machining difficulty. To make matters more complicated, industry is increasingly turning to small batches of high-value products. Developing the appropriate tools and processes for such machining is time-consuming and expensive, if they are not adaptable to the production of other components. Scientists working on the EU-funded project 'Adaptive control for metal cutting' (ADACOM) developed a generic and modular adaptive control hardware platform for metal-cutting processes to address this critical issue. This should decrease production time, waste and energy consumption while ensuring best practices for the cutting of new materials based on intelligent adaptation. The core components of the platform are adaptive machining systems consisting of advanced sensors and actuators for online control of manufacturing. A modular online quality control system was created with flexible compatible units that are selected on the basis of machining operations and end-use sectors. Researchers then developed a central machining system capable of implementing different solutions to accommodate changing production situations, different machine tools and various workpiece materials. Key to the ADACOM system's success was the use of standardised adaptive machining systems including plug-and-produce interfaces and standardised data formats. Standardisation enables the reconfiguration of production and sharing of data from the design phase through to mass production and quality control of the final product. Technology was optimised in several industrial case studies leading to the production of a demonstrator used for a life-cycle assessment to evaluate sustainability. ADACOM technology is expected to have significant impact on the manufacture of complex components made of alloys and composites with high quality and finish. Success of ADACOM technology will increase the competitiveness of the EU in the manufacturing sector as well as associated industries.