Automated orbiting laser beam meets industry requirements

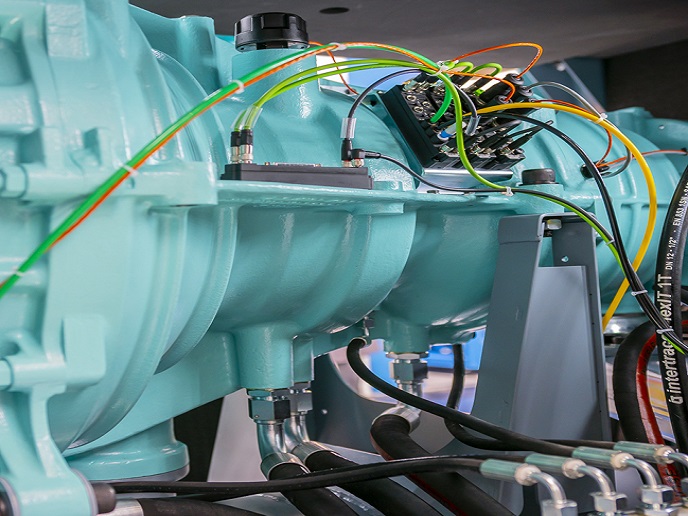

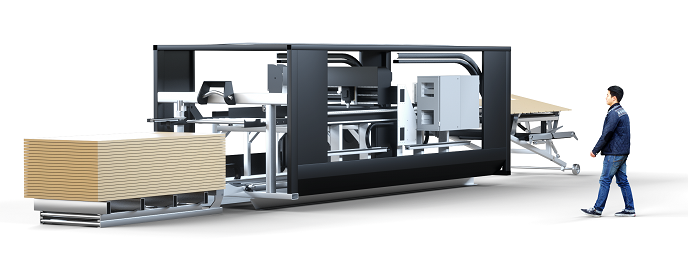

The European industrial shell and tube heat exchanger market is currently subject to intense competition and facing challenges due to rising metal and energy costs. The welding process itself provides a large window of opportunity to regain lost ground. Replacing conventional welding procedures with automated laser welding could increase product quality and welding speed while decreasing energy consumption. It requires overcoming current challenges related to compatibility with the large tube-to-sheet joints and interference from vibrations on the factory floor. With input from industrial partners, scientists developed the prototype for a novel laser welding head tailor-made for operations to produce large industrial heat exchangers with EU funding of the project 'Design, development and evaluation of an orbital laser welding head'(opens in new window) (ORBITAL). Orbital welding for joining tubes together has been around since the 1960s. In its current version, it employs computer-controlled rotation of a conventional welding gun around the tubes to be joined (i.e. in an orbital) with significant benefits over manual welding. Employing lasers in orbital welding under conditions of heavy external vibrations and, further, extending the process to cover joining of tubes to sheets are the important contributions of the ORBITAL project. The ORBITAL system consists of the orbital laser head, the industrial robot on which it is mounted (the computer numerical control (CNC) system), and the coupling and positioning systems. The laser head contains the lenses that shape and guide the laser beam to the workpiece. The control system ensures high accuracy, high-speed processing and real-time control. The robot is coupled to the orbital head for auto-centring of the welding head when it enters the tube and for enhanced accuracy and repeatability. The positioning system is clamped to the workpiece during welding and innovative mechanical coupling blocks vibration transmission from the workshop to the welding head. Scientists successfully delivered the required orbital laser welding system for tube-to-sheet welds required in the production of industrial heat exchangers. Given the continued growth of the European heat exchanger market and the stiff competition, ORBITAL technology is expected to have significant impact on EU manufacturers and the EU economy although the unit cost including installation is high.