Cutting-edge technology for green, cost-effective do-it-yourself house building

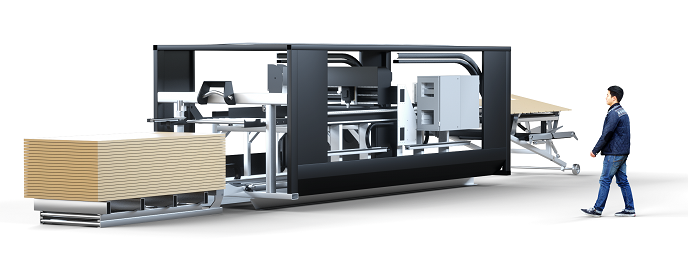

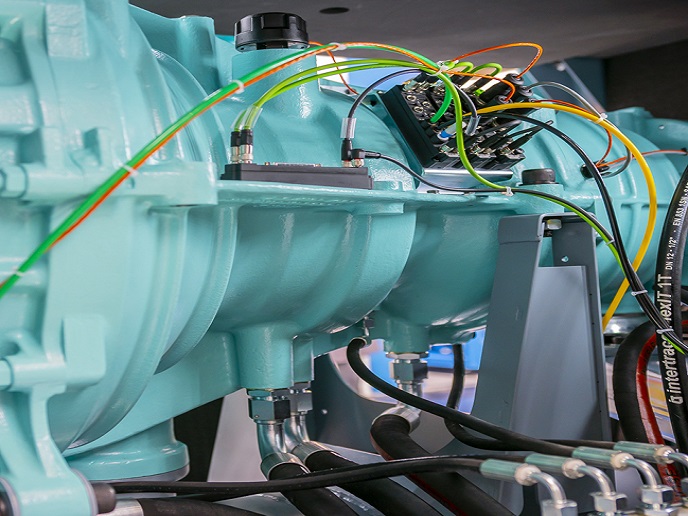

“Architecture isn’t just a roof over your head, it’s central to a happy and productive society,” says Nicholas Showan, coordinator of the EU-funded HouseBuildR HouseBuildR (Build your house exactly as you imagined it) project. “Give people homes they’ll love and they’ll perform better in life and work.” Showan emphasises that house building has changed little in the past 100 years. “There’s a need to build houses like we build cars, that is, from many precision components.” He also believes that focusing on building cheap accommodation for the poor is a false economy. “It will not engender a feeling of well-being in occupants, so the homes will be neglected and become rundown, as was the case with post-war tower blocks. People at all social levels are individuals and their homes should reflect this.” Rapid design and construction of green homes HouseBuildR devised a new method that’s able to create any architectural style to suit a wide range of personal and regional tastes. It will enable the construction of houses that are eco-friendly both to build and to run. The project team built and configured a sophisticated large-scale computer numerical control (CNC) machine that manipulates machine shop tools using computer programming. It will allow developers or self-builders to design a house online by selecting an initial model and then adjusting it to accommodate their individual preferences. Rooms, walls, windows and doors can be added and adjusted as required to create a totally individual design without any limits. Following the design phase, the data is downloaded to the mobile CNC machine that cuts the hundreds of plywood parts required to build the house. Users take the device to the building site to cut the 20 tonnes of plywood needed for a typical house. The parts are automatically cut by the CNC machine for rapid on-site assembly. This should minimise handling, damage, packaging and confusion. End-to-end house building automation solution While the twin-skinned box structure is being erected, ducting for electrical and other services is installed. The void is then filled with foam insulation creating a highly rigid and precise structure. This precision allows all downstream processes to be deskilled. After, the resulting monocoque core is clad in any desired material, including brick, slate, tile, wood and steel. In this way, any architectural style can be created, from reproduction period homes to highly innovative modern designs never before possible because of high costs. “The building costs are proportional to the materials used, not the design,” explains Showan. “Exciting architectural designs are possible at no extra cost.” Now that HouseBuildR has finished, project partners have submitted a grant application to secure additional EU funding. “If successful, we hope to be building our first houses within the term of the project which is three years,” he says. “Once fully developed, the HouseBuildR system will revolutionise the way we build houses today that are both eco-friendly and architecturally pleasing,” concludes Showan. “We will empower people who prefer to build their houses from scratch by letting them seamlessly manage a building project themselves and within budget.”