Revolutionary air compressor reduces energy consumption

Air compressors are used extensively in many industries. They supply air for numerous manufacturing processes. These machines are also collectively responsible for 10 % of total industrial energy usage in the EU. This amounts to around 10 TWh of power, and about 4.3 million tonnes of CO2 annually. The EU’s Energy Directive (2012/27/EU)(opens in new window) is pushing for improved energy efficiency. Yet air compressors seem to fall short due to old air compressor designs that leak air. This design is commonly used across low-pressure models called blowers and has barely changed since 1935. The EU-funded PureBlade project developed a much-needed improvement, which addresses the problem of wasted energy resulting from air leaks in compressor designs. The project developed a new type of air compressor intended for food and pharmaceutical applications. The team also developed economical manufacturing techniques, and marketing strategies.

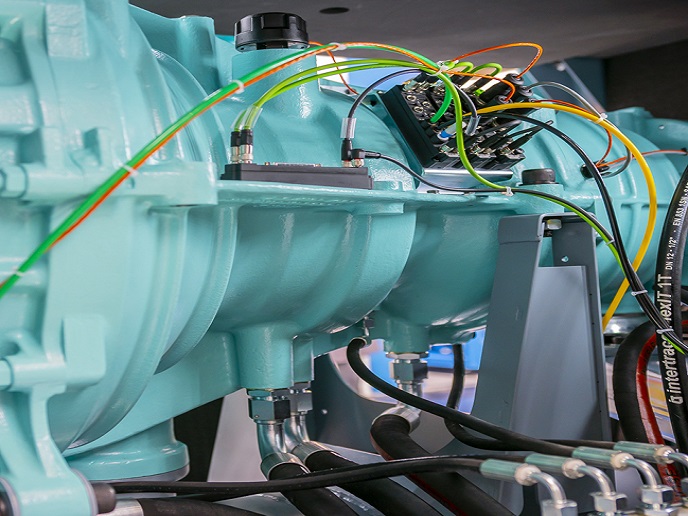

New compressor design improves sealing and silencer

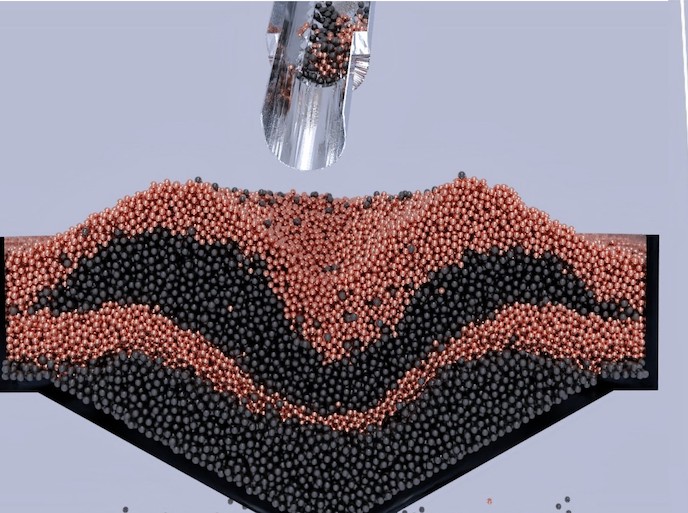

The new system, called Blade Compressor®(opens in new window), is designed around two interlinked rings. These provide an effective broad seal area, giving excellent efficiency at low rotational speeds. This simple mechanism makes the system oil free, and therefore suitable for pharmaceutical and food/beverage applications, which require high standards of air purity for hygiene reasons. Researchers developed the technology of lead partner, Lontra, to achieve high-level efficiency, reliability and air purity. They also improved the manufacturing process to the point where high-quality components can be produced economically. The project devoted special attention to the silencer component, in order to make the system quiet enough for low-noise manufacturing environments. Design engineering work also addressed ease of use, including maintenance.

Better than expected reliable results

The PureBlade team progressed from designing, to creating, and then testing full-scale design prototypes. Twenty percent energy savings were anticipated, but in-house and independent testing showed that the product exceeded expectations, achieving 34 % better efficiency than the nearest competitor. Testing also showed the system to be durable, and suitable for clean-air applications. These results put the Blade Compressor® far ahead of the competition. “During the first phase of the project,” explains Kiran Tailor, project manager, “we initiated engagement with end users. Since then, we have expanded this to ensure market needs are addressed, while raising awareness of the forthcoming new product.” The team is selecting the most appropriate companies to work with during the early adoption phase and developing a road map to roll out the new compressor. “Many distributors have shown a great interest in our technology,” adds Tailor. “The market turned out better than we had hoped.” Following a successful product launch at ComVac(opens in new window) in Hannover, the project team has since signed contracts with the first distributors. Given the performance gains compared to competitors and the high demand from customers, Lontra may become a new player in a global compressor industry worth over EUR 10 billion in Europe alone, and around EUR 53 billion globally. Current production estimates for the product may translate to a global energy saving of 0.5 TWh per year. This will significantly improve Europe’s industrial carbon footprint, supporting a greener world and more reliable future for air compressors.