Optimised inspection technology to boost aviation safety

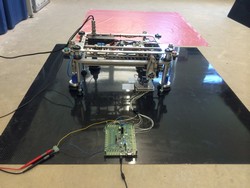

Composite materials help decrease the weight of many aircraft structural components, thus reducing fuel consumption. Nevertheless, the failure of primary structures – difficult to detect and almost impossible to repair – accounts for their narrow adoption by the aircraft industry. Since the introduction of structural materials based on carbon fibre-reinforced polymer (CFRP), there has been growing interest in portable testing devices. The EU-funded COMP-HEALTH (Radio frequency sensing for non-destructive testing of carbon fibre reinforced composite materials for structural health monitoring) project worked to develop a mobile scanner that can be used to detect defects in composite materials and components during the time of manufacture and in-service inspection. This technique includes the use of radio frequency waves for remote sensing and improved scanning speed to detect defects in a range of CFRP materials. Following sensor array design, sensor data acquisition and scanner system development, project partners built a portable, handheld and automated scanning system that detects defects in CFRPs. They integrated hardware and software into the system, and then proceeded with testing, modifications and optimisation. The solution provides users with a 2D image that indicates potential critical defects. The COMP-HEALTH team assessed the suitability and performance of the fully integrated system prototype. It successfully demonstrated system functionality and operations, as well as the system's ability to detect crack, hole, delamination, specific bubble and spread bubble defects of various sizes and depth. COMP-HEALTH's novel inspection system increases the probability and reliability of detecting CFRP defects, taking into account important factors such as low cost, fast scanning and portability. It should also boost the competitiveness of the European NDT industry.