Exquisitely precise nano-patterning

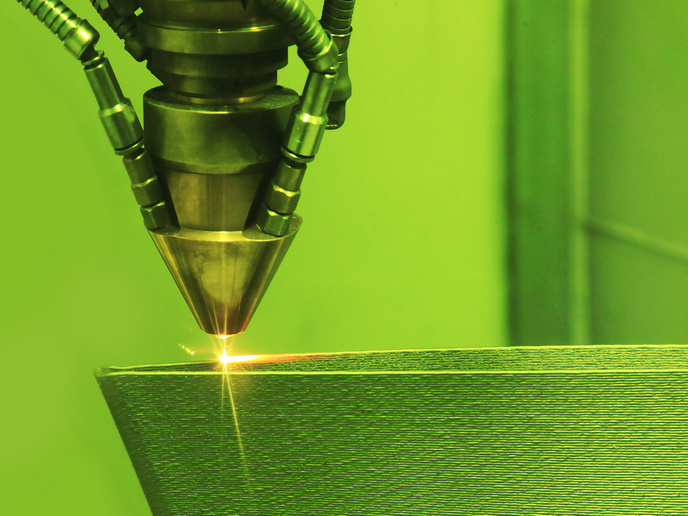

Formation of patterns on substrates such as that required for printed circuit boards have traditionally relied on imprint lithography. In this process, a polymer mask is used to transfer an image to a photoresist (photo-sensitive emulsion)-coated substrate. Resolution and precision can be limited by distortion of both the mask and the substrate during processing. New technology is required for today’s nanoscale structures. Maskless lithography uses focused radiation to directly write an image to the photoresist. It has many benefits including eliminating the need to produce masks for each process, enhanced resolution and high throughput. Development of new manufacturing technologies exploiting these concepts was the focus of the EU-funded project 'Laser nanoscale manufacturing' (LASERNAMI)(opens in new window) . Scientists have delivered technologies with many advantages compared to other advanced techniques including ion beam, electron beam, scanning probe and nanoimprint lithographies. The new approach is simple, inexpensive and versatile. It accommodates a long working distance and is compatible with various substrates for both two-dimensional and three-dimensional applications. Two interference lithography systems were developed exploiting it. One system has four beams and the other has a novel multi-wavelength laser (five different wavelengths) with beams numbering between two and six. Scientists achieved record-breaking super-resolution beyond the diffraction limit of light (down to 50 nanometres). The team used the new technology to fabricate a variety of devices including nano-gratings, anti-counterfeit security markers and nanosensors. Nanofabrication is pushing the frontiers of product development and will continue to be instrumental in the miniaturisation and functionalisation of devices in virtually every field. EU technology is set to play a leading role.