New materials for efficient power generation

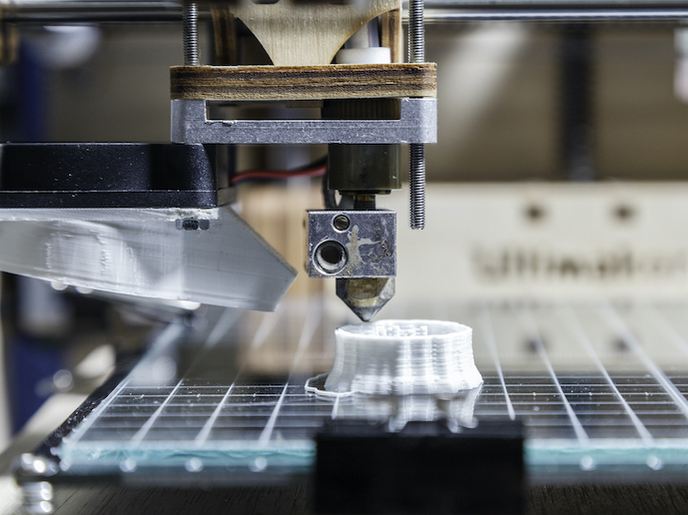

Oxide dispersion-strengthened (ODS) alloys are a class of materials that exhibit good mechanical properties and corrosion resistance at temperatures exceeding 1 000 degrees Celsius. Such alloys are produced by the mechanical alloying of powders and are well-suited for power generation. A number of economic and technical issues pose significant barriers to manufacturing components from ODS alloys. For one, processing ODS alloys with the currently available mechanical alloying equipment is time consuming and ineffective, leading to high production costs. Furthermore, their superior properties make it difficult to repair and manufacture them with traditional machining techniques. The EU-funded project OXIGEN(opens in new window) made excellent progress on all fronts – from the development of new ODS powder materials and production techniques to the development of flexible and efficient powder-based additive manufacturing routes for component manufacture. Scientists eventually opted to incorporate ODS particles into nickel-based and titanium aluminide alloy materials. The addition of yttria-based particles into powders of all selected alloys improved the homogeneity and distribution of the oxide particles after mechanical alloying. The team used a number of different methods including selective laser melting, laser metal deposition and sintering to manufacture test specimen for the demonstrators. Definitely noteworthy, the team managed to achieve a twofold increase in material corrosion resistance with some methods, a twofold reduction of part weight due to material density decrease (in the case of using titanium-aluminum alloys instead of the existing high-temperature steel alloys). OXIGEN produced three optimised components with embedded sensors for performance testing and monitoring by end users. The target was to achieve up to a 30 % increase in engine efficiency at exhaust temperatures above 615 degrees Celsius. The consortium comprised 11 organisations that are recognised leaders in ODS material development, powder production technologies, metal layer deposition and selective laser melting processes. The new materials should help reduce harmful transmissions and ensure increased safety in power plants.