Integrated framework for a cost-effective and ease of Repair, Renovation and Re-use of machine tools within modern factory

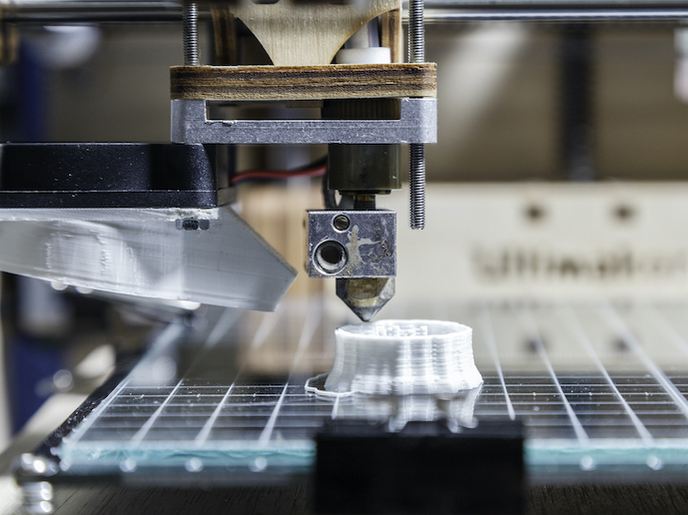

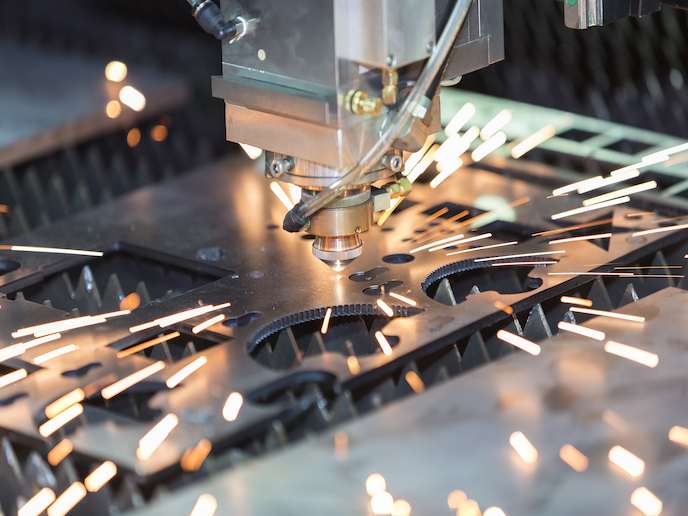

Current procedures for maintaining factory machines are generally useful regarding matters of quantity, and efficient scheduling, of necessary maintenance. Yet, such operations do not address effectiveness issues in terms of complete life cycle. The EU-funded EASE-R3(opens in new window) (Integrated framework for a cost-effective and ease of repair, renovation and re-use of machine tools within modern factory) project is focused on the selection of the best maintenance strategy, including decommissioning, according to the minimization of Life Cycle Cost (LCC) and Life Cycle Assessment (LCA). Then different technologies for supporting maintenance tasks such as Augmented Reality (AR)-based, Virtual Reality (VR), Condition monitoring are investigated. Moreover, platforms yielding best choices among options such as decommissioning, renovation, repair or reuse are available. The 14-member consortium further intends to recommend when certain maintenance technologies would best facilitate particular maintenance options. The three-year project concludes in June 2016. Team members produced methodologies supporting the integration of life-cycle costs and life-cycle assessments in terms of reliability and maintenance modelling. A prototype repair decision-support system (RDSS) has been produced, while various other items remain at an early stage of development, for example the Decommissioning Decision Support System (DDSS). Throughout the first phase, the project has collected data to be used for testing and validating the proposed methodologies. The group performed simulations for condition-based monitoring and prepared a prototype that uses augmented reality for industrial applications. As of month 16, there has been prepared an exploitation strategy, conducted other dissemination activities and prepared printed information materials. Contribution to standardization activities has been specified as one of the means for dissemination of EASE-R3 project results. Therefore relevant research results have been transferred into standardization. The EASE-R3 project will produce a method for determining best factory maintenance and re-manufacturing strategies and policies for particular long-term goals. The results should offer improved service to customers and reduce the risks of management decisions.