Industrial potential of composite components unlocked

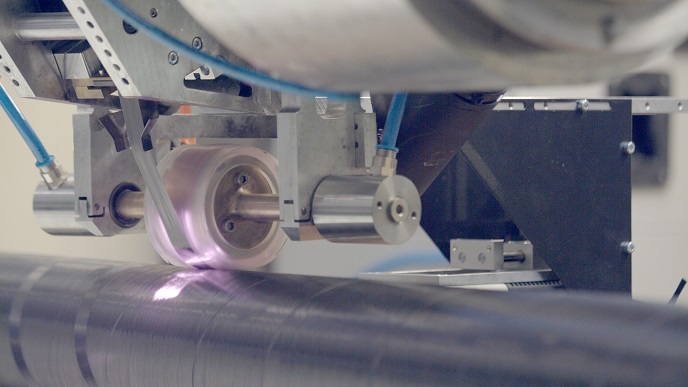

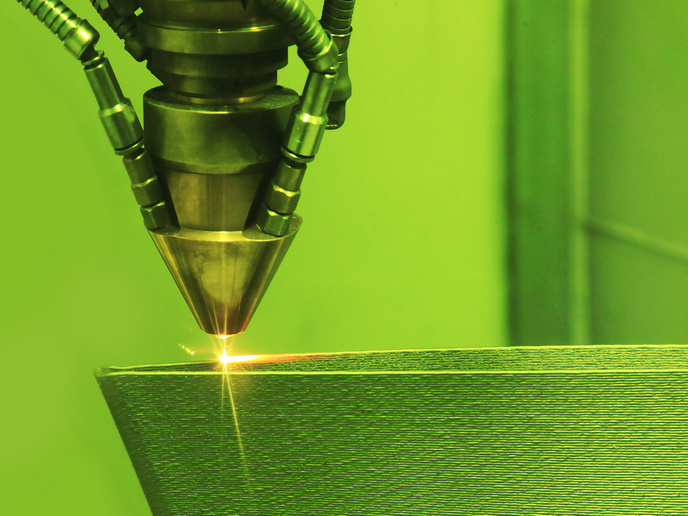

The key success of the ambliFibre (adaptive model-based Control for laser-assisted Fibre-reinforced tape winding) project has been to demonstrate that automated and reliable mass production of thermoplastic composite parts is possible by laser-assisted tape winding. Prototype machines capable of delivering pressurised tanks for the automotive industry and pipes for the oil industry have been developed, and the system’s modular technology is now available to industry. “Customers can come to our facility in Aachen and see the process in action,” explains ambliFibre project coordinator Martin Schäkel from the Fraunhofer Institute for Production Technology (IPT) in Germany. “From the range of new solutions developed by the multinational consortium, they can select precisely which technologies might fit their specific needs, such as the data mining or laser optics applications. As a research institute, we are of course keen to continue optimising and enhancing the technology with our partners.” Reinforced demand There has been growing global demand for tubular thermoplastic composite parts from across a range of industries. This is because these materials are flexible, resilient and lightweight, and can be processed without the need for pressure chambers or autoclaves. This makes them potentially cheaper and faster to manufacture than thermoset composites. Access to the mass market however has historically been hampered by the perceived cost of scaling up production as well industry reluctance to switch to new materials. “The automotive sector has a lot of experience with using conventional materials like steel, and relationships with suppliers have been built up over the years,” explains Schäkel. “We therefore have to first overcome scepticism within the industry by really addressing their need for efficient mass production, and by demonstrating this in a transparent way.” Visible benefits To do this, the ambliFibre project undertook a modular approach to build on and improve an FRP tubular part production technique called tape winding. Different technologies were selected and integrated into prototype processing machines, capable of manufacturing discontinuous products such as pressurised tanks for the automotive industry as well as continuous cylindrical products like oil risers. For hardware, a quality monitoring device was built into the system along with a thermographic camera to measure the quality of the part as it is being processed. This means that an operator has access to direct feedback during the manufacture of an FRP pressurised tank for example, and can adjust or even stop the process immediately if needed. The project team also built new adaptive laser optics to optimise the heat input in the process zone, where subsequent tapes are melted and consolidated, layer by layer. A high-speed thermographic camera was developed to measure the resulting temperature distribution in real time. On the software side, a data mining engine and a holistic process simulation model were devised to enable plants to optimise the process for their own specifications. Lifecycle modelling to assess the environmental impact of products and reliability modelling for the machine design complement the production system. This gives operators complete control and visibility over the automated process. “Industry interest was encouraged through public workshops with industrial stakeholders as well as demonstrations of our prototype machinery here in Aachen,” says Schäkel. “We’d now like to adapt the technology to new parts and applications, to see what the full potential is.” Project partners still collaborate even though ambliFibre has been completed. “This has been one of the most positive aspects of the project,” says Schäkel. “It brought together a great package of different competences and capabilities. We are always looking for new projects to further adapt the technology to industry needs.”