An unmanned, remote-controlled vessel to block oil spills

Developed with the support of the EU-funded OILBLOCK project, SpillPython(opens in new window) is an unmanned, remote-controlled vessel equipped with a compact, easily deployable oil spill containment system. “By blocking spills before they spread, our autonomous containment system aims to help organisations, policymakers and regulators better prepare for – and respond to – oil spills,” explains Boaz Ur, founder and CEO of HARBO(opens in new window), one of the project’s main partners. Although still in prototyping, the plan is to be able to install the system in such high-risk locations as ports, oil terminals, large tankers, and oil rigs. When a spill is detected, the SpillPython will automatically deploy hundreds of metres of boom, essentially a floating barrier, around the spill, containing the oil until it can be recovered and removed.

A winning combination

SpillPython’s development is a case study in the benefits of collaboration. According to Ur, the idea emerged from work being done by HARBO, which manufacturers innovative oil booms, and HEBO(opens in new window), a Dutch maritime service and oil spill response provider. “The idea of building an automated vessel seemed obvious,” he says. “We were able to connect with ASV(opens in new window), one of the world’s leading autonomous vessel systems, and together we got to work.” HARBO’s boom technology, the ASV innovative remote-controlled vehicle design, and HEBO’s years of experience in responding to oil spills proved to be a winning combination. “From the get-go, we were engaged in intense dialogue full of experience, knowledge sharing, imagination and creativity,” adds Ur. “The result of this collaboration is a roadmap for creating a system capable of automatically responding to oil spills.”

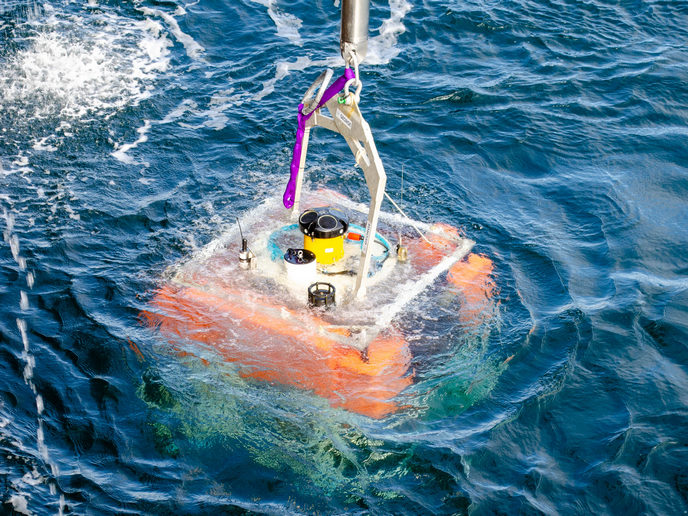

A prototyping vessel

The project was divided into units, with each partner responsible for specific components (e.g. boom storage, pneumatic door, etc.). “Thanks to this project, HARBO was able to develop an innovative multi-use boom,” notes Ur. “This means that if the oil doesn’t reach the boom, it can be repackaged and reused, adding an important sustainability component to the SpillPython solution.” One thing the team quickly realised was that sometimes what seems easy on paper turns out to be the trickiest riddle to solve. “Things like connecting booms together or to a ship are easy when a human is doing it, but become much more complex when trying to be done by a robotic vessel,” explains Ur. Following nearly half a dozen versions of the connector application, the team settled on the use of a magnetic version. The various components were eventually brought together, first via 3D modelling and, after size, weight and performance parameters were adjusted, as a prototype vessel.

From testing to commercialisation

At the end of 2021, the SpillPython prototype was ready for testing. “We are happy to report that our solution was able to contain a theoretical oil spill without any human intervention,” says Ur. “Not only is the SpillPython able to respond to spills faster and more effectively, because it is remotely controlled, it reduces the human risk associated with these spills.” With a proven design in hand, the team is now looking at fine-tuning the prototype and preparing it for commercialisation.