How new heating methods improve bio-based manufacturing

The industrial sector has no shortage of sustainability targets. The harder part is turning them into materials and processes that factories can run every day with predictable quality. The EU-funded GREEN-LOOP project(opens in new window) addressed that gap by developing bio-based alternatives and retrofitting manufacturing lines so these materials can be processed with tighter control and lower resource demand. Under Horizon Europe’s Digital, Industry and Space programme, the project designed and optimised three bio-based components: rubber panels for multifunctional applications, bioplastic bottle closures for oil, and wood-composite bearings for plastic injection machines. Alongside the materials, GREEN-LOOP looked at production, monitoring and end-of-life handling, aiming to minimise waste and improve circularity across each value chain.

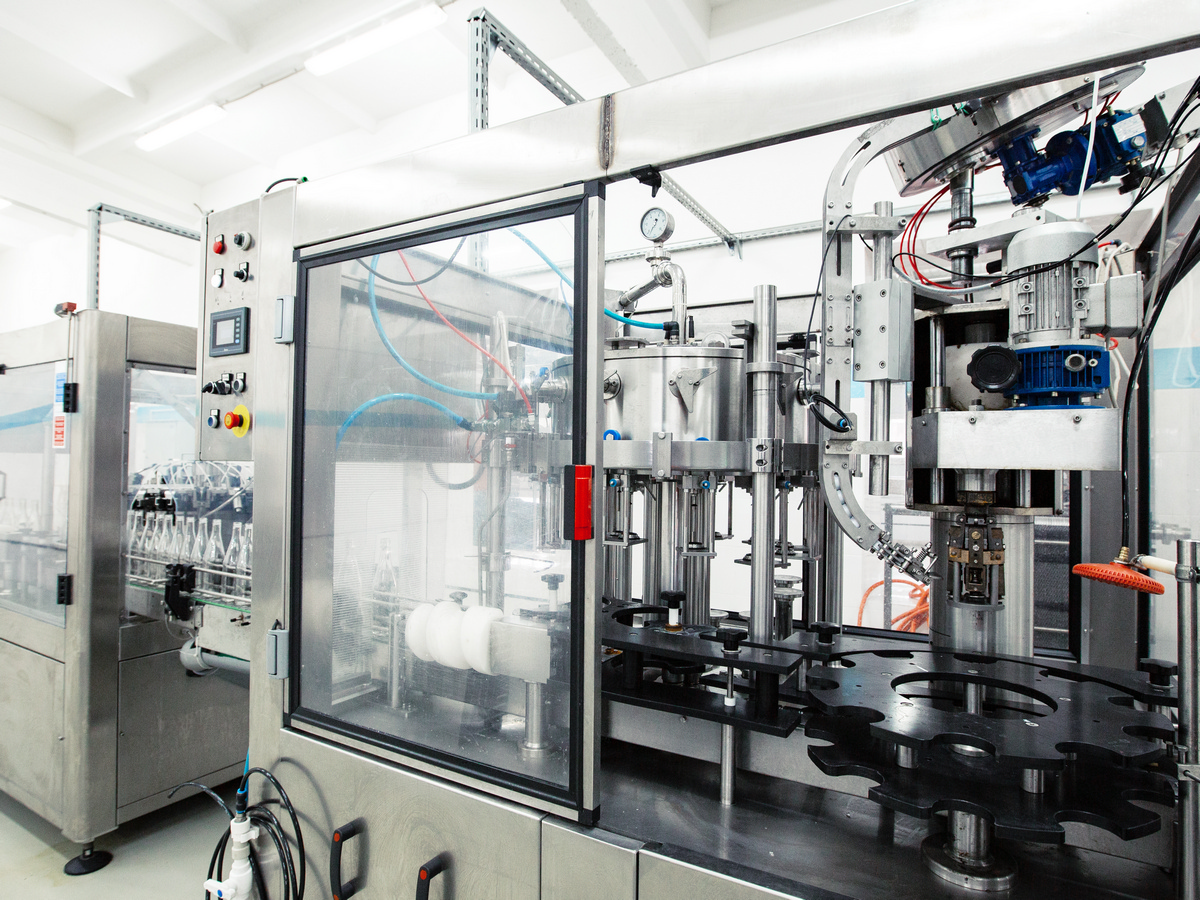

Retrofitting factory lines to process bio-based materials

Moving from fossil-based compounds to bio-based ones often exposes a fundamental problem: existing equipment was designed around predictable materials and stable processing windows. GREEN-LOOP focused on retrofitting, combining targeted upgrades with monitoring and digital optimisation so that current lines could be adapted instead of replaced. One of the main lessons concerned sensitivity during processing. As project coordinators Luis Enrique and Ignacio Fernández explain: “Bio-based materials are often more sensitive to formulation and processing conditions than conventional ones, so achieving comparable mechanical strength or wear resistance requires tighter control and smarter design.”

Microwave and ultrasound processing for cleaner, more efficient production

GREEN-LOOP tested advanced processing methods to improve energy delivery. Microwave heating was studied for extrusion and injection moulding, using modelling to guide equipment design and support more uniform heating. Ultrasound was integrated in multiple stages, including lignin extraction and rubber devulcanisation. By delivering energy closer to where it is needed, these approaches can shorten processing time and reduce thermal losses. In practice, the project reports energy savings, improved process control and the potential to lower emissions through these upgrades. Materials development ran in parallel, including the use of renewable resources such as cork and bio-based polymers, such as lignin. Moreover, additives are selected to support performance in specific applications.

Designing end-of-life routes that work outside the lab

“Improving production is only half the job if products still end up as waste,” the project coordinators say. GREEN-LOOP treated end-of-life as a design constraint rather than a downstream problem. The project’s life-cycle approach covered sourcing, manufacturing and use, while keeping reuse, refurbishment and recycling routes in scope from the start. This stage proved difficult for reasons that go beyond materials science. As the project coordinators state, “Optimising material manufacture across the entire life cycle has revealed that end-of-life management is often the most challenging stage in practice.” Real-world outcomes still depend on collection systems, recycling capacity and cross-sector alignment. In parallel, the project’s industrial demonstrations, together with the integrated assessment of performance, costs, and life-cycle impacts, also addressed a critical barrier to industrial adoption: hesitation driven by risk. The project coordinators underline that reducing uncertainty often matters more than incremental technical improvements. By pairing demonstrations with evidence throughout the life cycle, GREEN-LOOP helps decision-makers assess feasibility with greater confidence.