Predictive prowess for blow-moulding industry

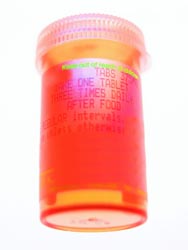

When molten plastic is injected into a steel mould and then inflated under pressure to take on the shape of the mould, ensuring uniform mould thickness throughout the product is a matter of fine-tuning. Often, such “fine-tuning” requires the mould to be returned to the machine shop for further development and even then, results in hundreds of rejected product items before satisfactory results are gained. Automated processes currently installed in most plastic industries, despite their advantages, do not really overcome such wastage, nor do they prevent the high cost of this trial and error process. ELFEN a commercial software package available from Rockfield Software offers a product that is capable of simulating and predicting wall thickness in blow-moulds even before the mould goes to the machine shop for production of prototype models. This predictive/forecasting capability contributes to a significant reduction in design time and design flaws. It therefore, improves the speed of which a new item can be produced for production purposes and allows a greater optimisation of material usage. In reducing design flaw potential and allowing for maximization of materials, a minimum 1% saving for the whole process can result in a Euro 23.5 million savings for the entire European plastics industry per annum. Reduction of flaws and hence reducing waste products can easily double this figure in purely financial terms. Saving time, reducing waste and its environmental impact, whilst cutting down on flaws in product design and overcoming the need for large powerful computers and expensive software, encompass the considerable benefits provided by the ELFEN software.