Simulating marble art

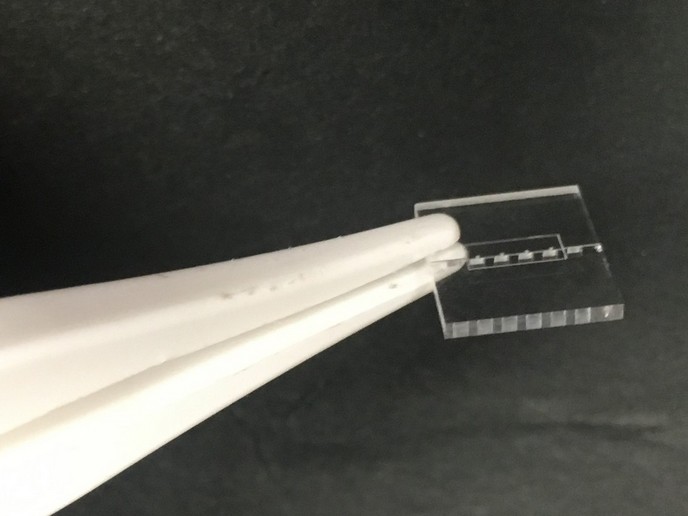

Until now marble dust and chips left over from cutting has been piling up in quarries and found use merely in road making and construction. However, this waste can now be used for artistic purposes by combining measurement and layering techniques based on laser scanning and digital photogrammetry, a three-dimensional museum exhibit copy (for example) can now be created thus celebrating function as well as form. The process is more delicate than it sounds since ancient marble can become contaminated or break if handled. Therefore the method needs to be carried out in a non-contact fashion and must be easily transported. In order for this to be accomplished, two digital cameras working together from different angles project a reference grid onto the object creating a cloud of reference points. Thin layers of marble powder spread over a base plate. A virtual image is then converted to a solid object using an applicator head that goes over each layer according to the computer data applying a liquid binder. The binder is saturated into the powder and hardened by a heating lamp. As is apparent from one of the first test pieces of the head of the ancient Greek goddess Hygeia, the finished product was hard, shock resistant and felt like stone. Furthermore such factors as temperature change, humidity and ultraviolet light did not seem to have any visible effects. This is bound to be promising for museums since they will be able to sell replicas that resemble stone far more than the usual ones made of resin. Additionally, museums may utilise the process for larger objects such as friezes and keep the originals indoors protecting them from harmful pollutants. What's more application potential could extend itself to building parts, marble tiles or domestic architectural aspects.