Giga advances for Nano structures

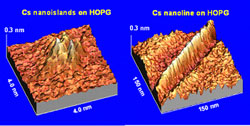

Atom lithography comprises a physical method where the trajectories of the atoms of an atomic beam are manipulated by means of interfering laser beams. In this way, atom lithography patterns a beam of atoms with a mask made of light leading to the fabrication of nanometer-scale structures. The NANOCOLD project aimed at the development of nanotechnologies based on the deposition of atoms focused by laser light, with an ultimate goal the fabrication of basic elements relevant for electronics, optoelectronics and information technology applications. In the context of the NANOCOLD project, nanostructures were grown onto a surface through the direct deposition of cold Caesium atoms. The cooling of an atom refers to the phase where an atom moving into the beam scatters many more photons than an atom moving away from the beam. This can happen by adjusting the frequency of the beam so that the net effect is to reduce the speed of the atom and thus cool it. The cold atomic beam of the apparatus is produced continuously out of a pyramidal magneto-optical trap (MOT) for Caesium atoms. The MOT is a specific configuration of mirrors mounted as a hollow pyramid, with a small apical aperture, in which the cooled atoms are confined to a small volume. Direct deposition of the cold Caesium atoms onto a surface was carried out, combined with in-situ microscopic diagnostics through Ultra High Vacuum (UHV) Scanning Tunnelling Microscopy. Highly Ordered Pyrolytic Graphite (HOPG) substrates, a relatively new form of high purity carbon, were used for the direct deposition of cold Caesium atoms in the presence of standing wave optical mask. However there has been difficulty in performing observation of a regular array of Caesium nanolines due to the relatively small dimensions of the atomistically flat regions of the substrate. Consequently efforts have been concentrated in the investigation of single, isolated lines, demonstrating remarkably good results. Caesium is highly reactive in air and its manipulation, deposition and investigation are very demanding. The project's outcomes enrich the knowledge and the relative literature of the specific diffusion used and growth phenomena met in the implemented regime. Further work must be done in order to clarify the role of process parameters and of substrate features in determining the shape of the deposits.