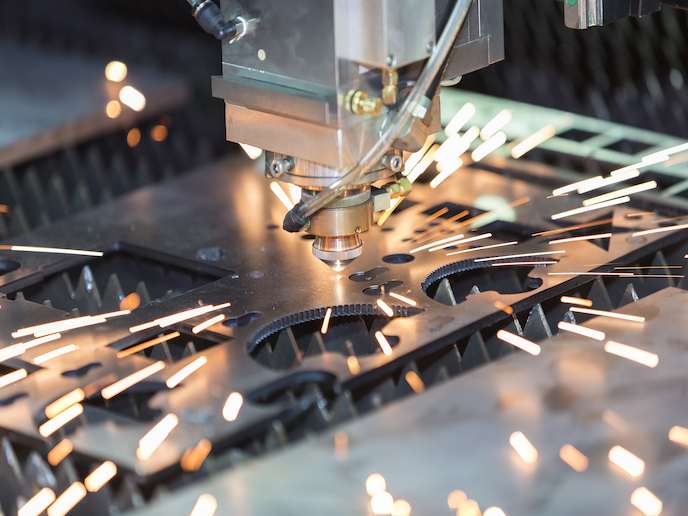

Innovative smart materials for universal fixtures

In recent years, conventional fixture technology has advanced significantly. However, deformations associated with temperature increases as well as insufficient attainable clamping force have resulted in solutions that, while flexible and reconfigurable, are far from universal. The ‘Completely flexible and reconfigurable fixturing of complex shaped workpieces with magnetorheological fluids’ (Maffix) project was undertaken to use state-of-the-art smart magnetorheological (MR) materials to produce innovative universal fixtures. MR materials quickly and reversibly change their consistency in the presence of a magnetic field and thus can adapt to the outer shape of any component, facilitating clamping and supporting the cutting forces applied. Researchers tested the newly developed MR fixture under real machining operations, validating its ability to clamp and hold the component under force from the machining tool. In addition, due to its excellent clamping ability, machine cutting force was increased, resulting in a significant decrease in process time. The project outcomes have the potential to increase the competitiveness of SME partner fixture manufacturers in existing markets as well as create the opportunity to compete in new application fields. In addition, SME partners that rely on fixtures for manufacturing could see an increase in product quality together with a drastic reduction in final cost of components due to a reduction in manufacturing and delivery time. Furthermore, the universal fixture has the potential to increase their competitiveness in small scale production of custom parts that heretofore was not economically feasible. In summary, the Maffix project team delivered a truly universal fixturing tool based on smart MR materials that could dramatically increase the competitiveness of European manufacturing SMEs with important effects on jobs and the economy.