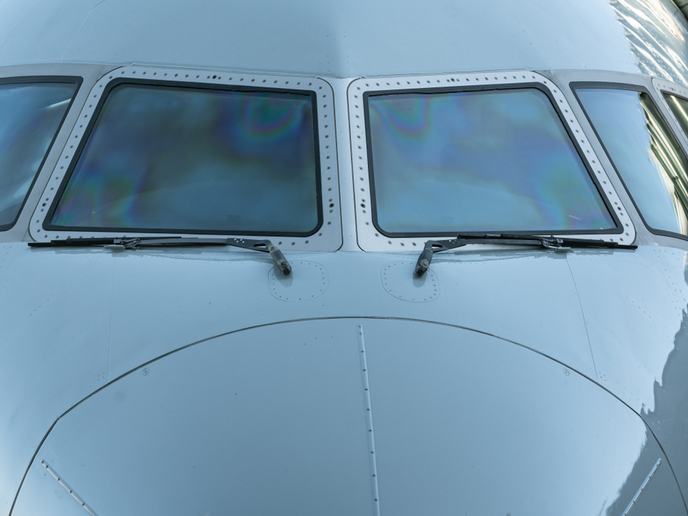

Better assessment of composite aircraft structures

In order to increase its competitiveness, the European aeronautical industry needs to reduce its costs. One of the key areas for cost reduction is the verification of composite structures, which involves a large number of tests and inspections for various purposes, such as material qualification, establishment of design data, static and fatigue life confirmations. At the same time, it is highly important to maintain the overall trend to increasing the level of quality and safety of structures. Motivated by this, a joint European effort from many research institutes and industries resulted in the development and validation of a cost-effective method for efficient design and verification of composite structures (EDAVCOS). With the aid of experts on airworthiness, and based on the results derived from the application and validity of this method, the consortium succeeded in proposing a new improved and cost-effective verification procedure for composite structures.The developed method was applied on many generic wing and fuselage structures comprising sandwich panels, stiffened panels, shear webs and bolted joints. The well instrumented tests also involved failure analyses of the specimens which provided valuable information on failure modes that was used for further improvement of the method. Specified by the project results, the new verification procedure includes not only inexpensive and rapid testing of structures, but also new means for fatigue testing, handling of impact damages and environmental effects. For this reason, it is also highly applicable to the wider composites industry. Particularly for the aeronautical industry, the project results are anticipated to add significant value to the aeronautical technologies with respect to their cost-efficiency, weight reduction and safety.