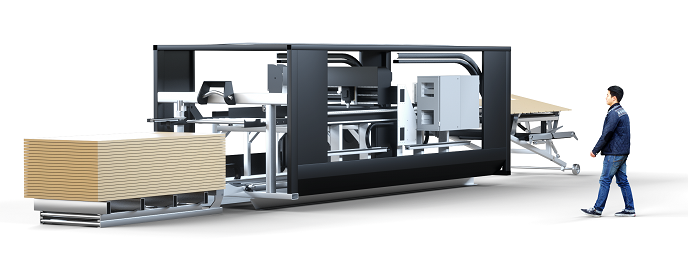

Unique products for unique customers

The EU-funded project 'A web-based collaboration system for mass customization' (E-CUSTOM)(opens in new window) sought to engage customers in designing personalised products and to enhance decentralised manufacturing.To bridge the gap between mass production and mass customisation, the project envisioned a web-based system that customises products with regard to features such as materials, shape and appearance. It worked on a tool to encourage manufacturing and/or assembly of selected parts outside the central manufacturing site — i.e. by associated suppliers, service providers or local distributors — thus supporting a smart, decentralised approach.In parallel, E-CUSTOM worked on measuring the environmental footprint of possible manufacturing solutions to home in on the most appropriate one. Such an efficient and eco-friendly approach can help overcome the challenges that European manufacturers are faced with, adding value to products and spurring innovation on a large scale. It aligns production with actual consumer demand more effectively, and shortens the design time for personalised products by up to 15 %. More specifically, the project team worked on developing a user-adaptive design system representing user-friendly design tools that enable customers to effect unique design changes in their order. E-CUSTOM then developed a decentralised production concept and an environmental assessment module in order to help select the most appropriate supply and/or manufacturing schemes. The last part of the project involved creating the required infrastructures in terms of network and information and communication technologies to standardise data exchange. This would facilitate communication among individuals and user groups. In essence, the project team introduced radical changes to the organisational and operational structures of today's manufacturing sector with a focus on assembly-intensive production such as the auto industry. This could lead to savings in energy consumption by as much as 10 % and in transport costs by as much as 20 %. The cost of raw materials will also decline, as will time to market and delivery. The new E-CUSTOM tools are expected to lead to an increase in market share of up to 10 % for European manufacturing, rendering it more competitive than ever before.