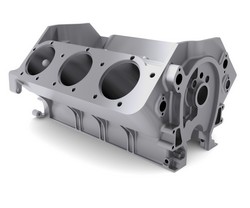

Eco-friendly low-porosity casting

The drive for improved fuel efficiencies in the automobile industry has led to continuing growth in aluminium die casting. Casting larger and more complex parts has created new challenges for die casters in their quest for improved quality and productivity. Porosities inherent to the fabrication process limit the widespread use of aluminium high-pressure die casting (HPDC). Although inexpensive adaptable high-vacuum processes can significantly reduce porosities, the highly complex nature of this process has made die casters reluctant to adopt this option. An EU-funded consortium established the SOUNDCAST(opens in new window) (Vacuum-assisted high pressure die castings with reduced porosity at low cost) project to produce weldable high-performance castings using low-cost vacuum-assisted HPDC. Project partners fabricated a die for evaluating alloy mechanical properties and vacuum-assisted HPDC. A new recycled alloy with improved mechanical properties was also developed through microalloying. The optimised fabrication technology enabled large, thin-walled and complicated component development with recycled aluminium alloys of minimal porosity and excellent mechanical and welding properties. Use of recycled alloy not only cut down on fabrication costs but also carbon dioxide emissions. The creation of new innovative control software suitable for low-cost vacuum-assisted HPDC processes ensured process stability and casting quality of SOUNDCAST technology. Furthermore, these benefits are applicable to conventional HPDC processes. Advances associated with SOUNDCAST technology has provided high added value to the automotive sector, enabling them to achieve high standards that were previously only possible through the expensive high vacuum die casting process. SOUNDCAST clearly demonstrated that mechanical properties and weldability were significantly increased compared to conventional high pressure die castings. Furthermore, values are comparable to those obtained by high vacuum processes. This makes the technology suitable for structural automotive applications. This includes chassis parts such as A, B, C pillars, shock towers and various nodes, and to a lesser degree parts for the suspension. Thanks to the consortium's efforts, the aluminium component market can be extended to lower-class vehicles. With low-cost high-quality technologies, the European casting sector can now compete more effectively in the global marketplace.