Novel method to inspect the quality of fish products

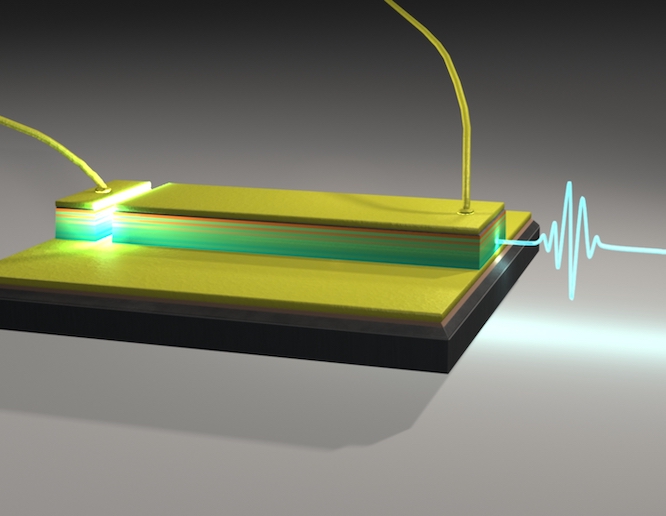

Traditionally, quality inspection has been based on visual inspection. However, this method is labour intensive and is dependent on the experience and criteria of the inspectors. In addition, many attributes affecting quality and safety are invisible to the human eye. Current instrumental measurements are unsuitable as they are expensive and time consuming and result in destruction of the sample. They are also unable to provide spatial distribution information for those critical attributes used to evaluate quality and food safety. To address the issue, the EU-funded SPECTRAFISH(opens in new window) (Hyperspectral imaging technology for the quality inspection of fish products) project set out to develop an inspection technique that integrates conventional computer vision and spectroscopy technology to create unique imaging sensors. The SPECTRAFISH team designed a laboratory test rig based on hyperspectral imaging (HSI) technology in order to train and validate several quantitative models for measuring the quality and safety features of finfish fillets. These were measured using traditional instruments and sensory analysis. Project partners built an HSI system prototype for a cost-effective, rapid, reliable and non-invasive method for measuring quality control in fish products. Hardware and software was also developed and integrated into the prototype. The prototype was successfully validated at a fish processing plant. SPECTRAFISH outcomes will boost the competitiveness of the European fish industry by automating inspection and saving on time needed for processing. This should lead to more product throughput and fish production, greater shelf life, less spoilage and reduced risk of fish recontamination.