Are microalgae the answer to a sustainable future?

Microalgae(opens in new window) are industrially valuable microorganisms and can serve as a source of proteins, polysaccharides and other bioactive compounds including omega fatty acids. Bottlenecks in the large-scale production of microalgae, including cost and process capacity, have limited their widespread use. However, the past 10 years have witnessed an increase in microalgae production in Europe, with demonstration facilities being launched with the support of EU funding.

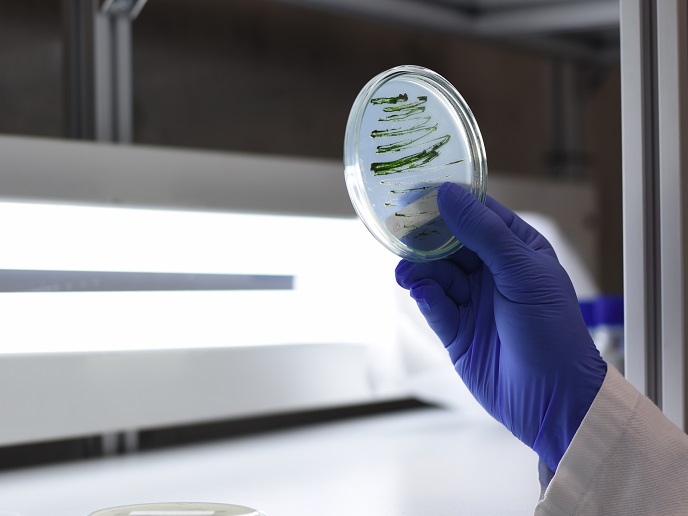

Improving microalgae production at industrial scale

The EU-funded MAGNIFICENT(opens in new window) project took advantage of the growing efforts in microalgae development, testing and production to further expand the portfolio of algae ingredients for the food, aquafeed and cosmetics industries. “Our main objective was to set up a sustainable and economically viable biorefinery chain for converting microalgae biomass into new products,” explains project coordinator Maria Barbosa. The project brought together 10 SMEs, 2 large companies and 3 R&D institutes with complementary expertise that undertook an economic, market and technological assessment. Different technologies were examined and integrated into a production value chain. Much attention was also given to ensure that safety and quality criteria of new products were in line with EU legislation on food, aquafeed and cosmetics. Partners collectively improved microalgae cultivation protocols to allow higher productivity with 30 % reduced energy and water consumption. Their work focused on three different microalgal species one of which was cultivated for the first time in industrial-scale tubular photobioreactors. The project implemented various process advancements that significantly improved the efficiency in obtaining several microalgae extracts.

Novel microalgae-based products

MAGNIFICENT identified and functionally characterised several algae extracts that led to the development of new ingredients that were then tested in food, aquafeed and cosmetics products at pilot scale. A prime example is an extract rich in the natural antioxidant oleoresin used to extend the shelf life of butter, pork sausages and aquafeeds. A similar extract was successfully used in an anti-ageing cosmetic serum prototype. Additionally, a water-soluble β-glucan extract showed an immunostimulatory effect in farmed fish as well as a potential to reduce cholesterol levels that could be exploited in functional beverages. Moreover, researchers identified peptide/lipid extracts with strong antimicrobial activity against oral cavity pathogens, which raises interest in oral care, confectionery and pet food applications.

The next MAGNIFICENT steps

Validation of pilot-scale data led to the design of an integrated biorefinery pathway for each microalgae strain. “Results from functional prototypes were very promising but more effort is needed to comply with market quality standards, prices and legislation, especially in the food-nutraceuticals sector,” emphasises Barbosa. The life cycle assessment of the microalgae biorefinery chain indicated that further reductions in energy consumption in the cultivation stage are important to enhance sustainability. Furthermore, scale-up of production facilities and increase in production are required to boost economic and environmental performance. Overall, MAGNIFICENT promoted the exploitation of natural and sustainably sourced raw materials for the development of microalgae-based products. Importantly, it considered consumers’ interests with respect to healthier foods, naturalness of skincare cosmetics and higher welfare status of farmed fish. The project received funding from the Bio-based Industries Joint Undertaking, a public-private partnership between the EU and industry.