A pioneering family of vitrimers for aerospace applications

The introduction of composites to the aerospace industry has had a tremendous positive impact. Composites have increased structural strength and improved heat, corrosion and impact resistance while reducing weight, fuel consumption and emissions relative to metal counterparts. Conventional thermoset composites are still the mainstay of aerospace components. Their cross-linked polymer chains instil excellent mechanical, thermal and chemical properties; however, they cannot be reprocessed upon heating (their structure is ‘set’ during the original heating and cooling cycle), which limits their repairability and recyclability. Thermoplastics, on the other hand, exhibit reprocessability, repairability and recyclability (3R). They are gaining ground in aerospace applications; however, the raw materials are expensive and processing requires high temperatures meaning significant energy input. The EU-funded AIRPOXY(opens in new window) project delivered the best of both worlds in a family of thermoset composites for the aerospace sector that exhibits all the advantages of thermoplastics. Its sustainable 3R resin for carbon fibre composites will slash time, cost and resource use – green skies are on the horizon for Europe’s aerospace sector.

3R resin: the pioneering patented vitrimer spreads its wings

AIRPOXY’s patented epoxy-based 3R resin is a vitrimer, a recently discovered class of plastics derived from thermoset polymers. Thanks to their thermally activated and reversible (‘dynamic’) bonds, they can change their topology via rapid bond-exchange reactions while keeping material structures and properties intact. Project coordinator CIDETEC(opens in new window) has continuously evolved the 3R resin for new composite applications over the last decade. The AIRPOXY consortium took these applications to new heights, tackling the extremely demanding requirements of the aerospace sector.

Vitrimers for aerospace: slashing the cost and time of production and repairs

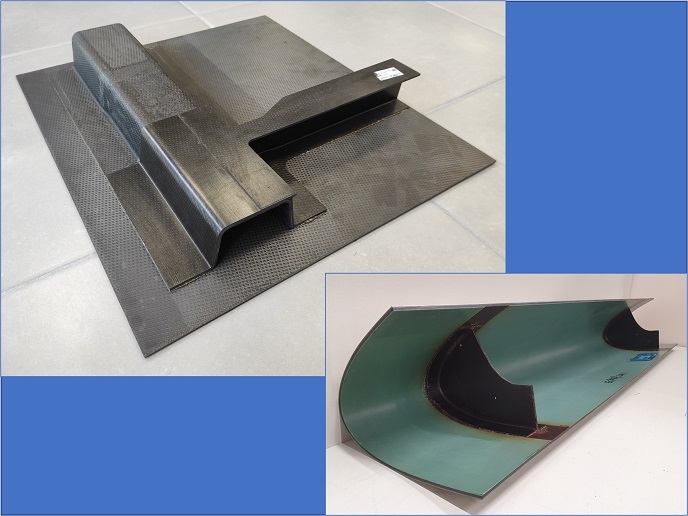

Extending the application of the patented 3R resin to the aerospace sector required development and application of simulation and structural health monitoring tools. AIRPOXY addressed processing technologies, including thermoforming, resin transfer moulding, welding and adhesive bonding, as well as repair. According to project coordinator Nerea Markaide of the Polymers & Composites Unit at CIDETEC: “Producing the 3R resin based parts with continuous compression moulding is 7 times faster and approximately 37 % less expensive relative to using an autoclave. Repairs to AIRPOXY resin composites can be made 95 % faster and at much lower cost; for example, delaminations can be repaired by applying heat and pressure on the damaged area without having to remove and rebuild it as with thermoset composites.”

3R resin conserves valuable resources

Life cycle assessment tools demonstrated clear environmental benefits of substituting conventional epoxy resin with 3R resin for carbon fibre composites manufacture. “Reprocessability or repairability via reshaping or remoulding reduces fatal production flaws and significantly reduces waste. Recyclability via solvolysis(opens in new window) delivers a cost-effective source of high-quality carbon fibre and 3R resin for reuse. Further, the 3R welding and 3R repair processes significantly reduce the use of energy and consumables,” explains Markaide. The aerospace sector is demanding increasingly sustainable materials and processes, driving a steady rise in the aerospace composites market size, expected to reach close to EUR 30 billion by 2026. AIRPOXY’s optimisation of its 3R resin properties to meet aerospace industry specifications(opens in new window) and development of procedures for thermoforming, repair and welding will enable the sector to achieve its ambitious goals while enhancing the competitiveness of the European aerospace industry.