Cultivating microalgae for sustainable proteins

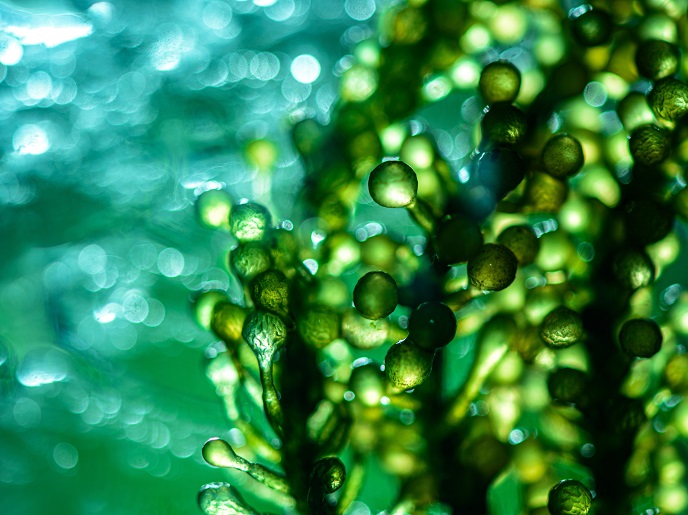

Microalgae have the potential to be a major green source of protein to feed the world. “This is by far the most sustainable source of nutrition on this planet,” says Yonatan Golan(opens in new window), CEO of Brevel(opens in new window) in Israel and BREVEL project coordinator. Microalgae use light and CO2 to grow very efficiently in terms of resources. Yet the process of growing microalgae is currently very slow, meaning production costs are high. Current systems also suffer from recurring contaminations, increasing time and cost through extra labour. Using light requires a very large surface area. Through the EU-funded project BREVEL, a start-up developed a new technology that scales and speeds up microalgae production. The team created a microalgae protein to be incorporated in plant-based products for human consumption.

An alternative cultivation solution

One alternative to growing microalgae with light is to introduce sugar into the process, leading to fermentation which increases growth rates by around 100 times, a much more efficient and cost-effective procedure. However, fermentation is done today only in the dark, and in the absence of light almost all of the nutritional value, relevant ingredients and eventually commercial value are lost in the process. Brevel has created a new photobioreactor, the first globally to combine fermentation with photosynthesis in a single process. “We have extremely high growth rates and low costs of production, and also have all of the benefits of having light in the process: high nutritional value, a variety of ingredients and functionalities, and a much higher commercial value of the microalgae,” adds Golan. The combination is well known, but no one has been able to do it beyond lab scale. “Through our technological breakthroughs, we managed to break through the glass ceiling and bring this new technology to the industry,” Golan notes.

Bringing the technology to a commercial level

The patented technology is able to generate consistently high yields, and the finely tuned light produces abundant microalgae at cost parity to other alternative proteins. Through the process, the BREVEL team spoke with many customers and partners in the industry to gain insights into what was needed in the alternative protein. In early 2022, the team was able to use their facility to create a tasty, sustainable and affordable white protein extracted from microalgae which they were able to produce. “We made a bold decision to shift our efforts to this new product and market,” remarks Golan, away from their previous focus, aquaculture feed. “This transition made our vision and mission very clear, providing sustainable nutrition for our planet.”

Feeding the world with microalgae

“Having Horizon 2020 by our side gave us the confidence that we have a serious and devoted partner that is moving forward with us,” Golan notes. “The European Commission has been supportive of our green vision all along the way.” Soon, the team will move into a new commercial factory, in which they will be able to scale production. “In parallel we are already negotiating and signing agreements with partners to establish large-scale manufacturing facilities in different locations globally, to ramp up production and meet the global food industry’s needs for millions of tons annually,” Golan says.