Selective production of ethanol and ethylene from CO2

Mitigating the accumulation of CO2 in the atmosphere and its impact on climate is imperative for the health of our planet and the well-being of its inhabitants. Decarbonisation, carbon sequestration and carbon recycling will likely all play essential roles. CO2 reduction during photosynthesis is nature’s way of recycling atmospheric carbon to store and release energy and to make other molecules. In industry, the electrochemical CO2 reduction reaction (CO2RR) is one of several promising strategies. It can be used to produce high value carbon-containing fuels and chemicals including carbon monoxide (CO), ethanol and ethylene. Although the CO2RR process fundamentals have been established at lab scale, engineering optimisations were required to make commercially viable devices. The EU-funded SELECTCO2(opens in new window) project addressed this pressing need, improving the selectivity and efficiency of the process while enhancing the durability of the device’s components.

CO2 reduction mitigates CO2 accumulation and reliance on fossil fuels

CO is typically produced via steam reformation of natural gas and ethylene by breaking down long-chain hydrocarbons in fossil fuels. Fermentation of biomass emits one CO2 molecule for every ethanol molecule produced. According to project coordinator Brian Seger of the Technical University of Denmark(opens in new window), “Our process starts with 100 % CO2 and then uses electrical power and water to convert CO2 into useful molecules. CO is an intermediate in CO2 conversion to ethanol and ethylene, so if we start with CO we are effectively skipping a step. This makes outlet streams containing CO beneficial. The insights of our industrial advisory board member Tata Steel were quite valuable as the steel process produces considerable amounts of CO2 and CO.”

Optimising a CO2RR device towards commercialisation

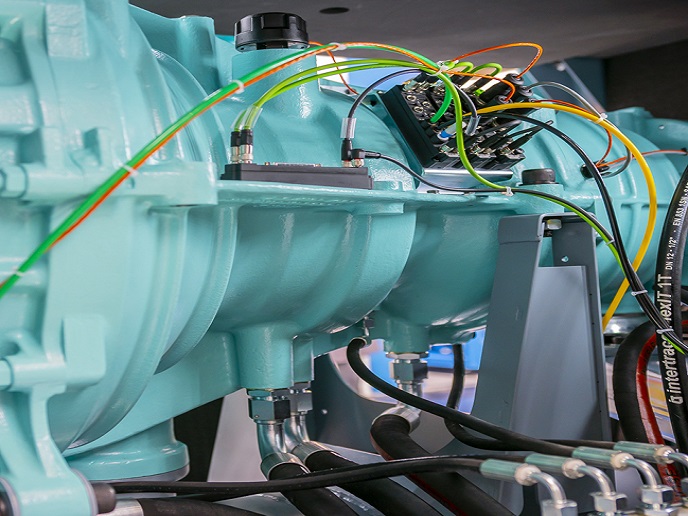

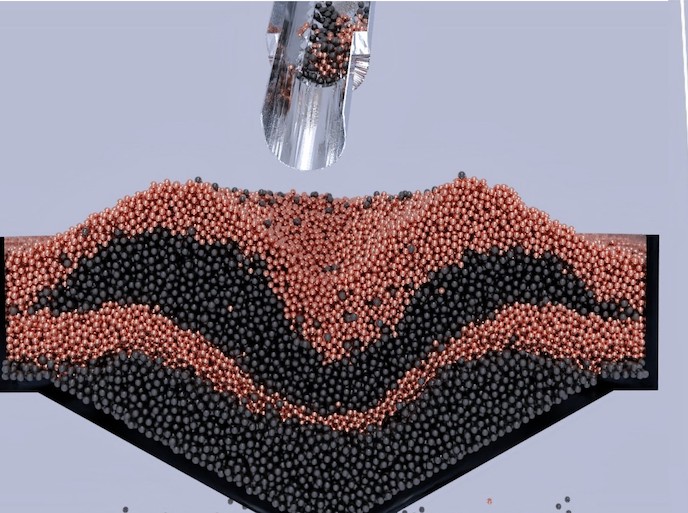

SELECTCO2 set out to make better CO2 electrolysis devices by improving the performance of the catalyst, gas diffusion layer and membrane and their integration. A multiscale mass transfer model was instrumental in improving the commercial prospects of the device. “We discovered the reaction mechanisms making it hard to separate ethanol from ethylene production, explaining our difficulty in obtaining good catalyst selectivity. Further, we determined the branch point where the reaction proceeds either to ethanol or ethylene, a huge benefit moving forward so we can investigate ways to shift selectivity,” Seger notes. In the meantime, thermal catalytic processes can easily convert between these species, either adding water to ethylene or removing it from ethanol. The combination of experimental and computational studies led to fruitful device optimisations. Before SELECTCO2, the CO2RR in electrolysis cells typically achieved current densities around 10 mA/cm2 for 1-hour experiments at lab scale. SELECTCO2 has advanced this tremendously with current densities greater than 200 mA/cm2 – even reaching more than 1 000 mA/cm2 – and more than 100 hours duration. “We have developed world-class anion exchange membranes as conductive as commercial membranes but that can operate at higher temperatures and are more mechanically robust. Our gas diffusion electrodes showed excellent performance compared to commercial benchmarks and we are working on patenting them. Finally, we successfully enhanced the activity of our CO2-to-CO electrocatalysts by using single site catalysts. They are now among the most active and selective available,” explains Seger. This step change in performance brings sustainable CO2-mitigating CO2RR electrolysis out of the lab and closer to market.