Lasers remove post machining testing requirements

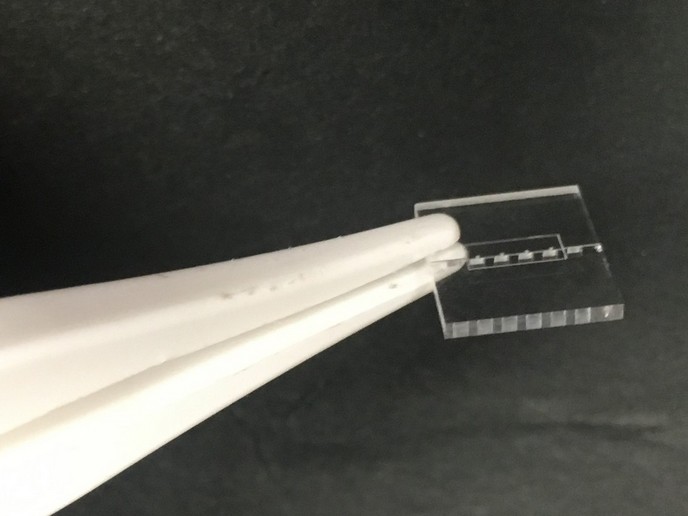

Conventional welding and cutting techniques can be imprecise and influenced by the amount of human intervention, such that the quality of the finished work can become flawed. The required heat generated at the focal point combined with the seam length varies from one engineer to another and depends purely on his or her own workmanship skill. Also the quenched and tempered material can be softened to varying degrees along the seam length, thus affecting the relative hardness of the materials surrounding area. However, laser welding and cutting techniques have significant advantages over conventional methods because of their finite precision application methods, and because there is no tool wear. In addition, the materials to be joined are more stable due to reduced thermal stress, and welding seams can be performed much faster. Laser cutting is also able to benefit especially in fine cutting applications used in the medical and microelectronics industries. The complete Laser cutting and welding system that has been developed is made up of software and hardware components. It is this combination that permits the laser to analyse the relevant cutting and welding signals, and identify any deviations from the reference parameter values during processing. Furthermore, during the condition monitoring, the system is able to monitor the state of the raw laser beam and the cover slide dirt. In order for the information to be electronically conditioned and filtered, the CAN bus communication tool and sensors provide the necessary information for the process and conditioning monitoring. It is then processed by the monitoring and supervision software; thus permitting its storage and future retrieval in both graphical and statistical formats. The overall benefit gained by this demonstration system, facilitates the elimination of quality testing efforts after machining, because the online process quality inspection functions at 100%.