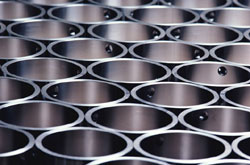

Centrifugal casting

The process of centrifugal casting has been used successfully for the production of a number of products ranging from pipes and boilers to hip and knee replacements. Although this is an extremely successful system, there are some drawbacks. Some of these include difficulty in coping with sensitive metals and the removal of impurities from the structures formed, which limit its expansion in more sensitive areas. In the process of centrifugal casting, a permanent mould is rotated about its axis at high speeds of up to 3000rpm as the molten metal is poured. The molten metal is thrown towards the inside mould wall where is solidified as it cools. The process is carried out in a vacuum and any impurities are segregated. The casting is usually of a fine grain with a very fine grained outer parameter which is resistant to atmospheric corrosion. The inside diameter has more impurities and inclusions. A completely automated process was developed which addressed the problems faced in the handling of sensitive metals like titanium. Specifically the casting process was carried out under a secondary argon vacuum where several cycles were carried out under argon. To avoid any contamination of the titanium metal, melting was induced either in a ceramic crucible or from metallic bars. The process is completely automated which ensures that reproducible conditions can be applied, thus producing identical products. Casting technologies were established for pure titanium, Cobalt-Chromium and Nickel-Chromium alloys. Results on demonstration trials are available which highlight this highly successful casting process. There are countless possibilities for the use of this technique in metal applications.