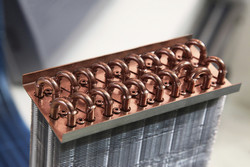

Cleaning heat-exchangers

About 65 % of all chemical and power-generation processes use a particular kind of heat-exchanger system. Such systems are prone to deposition of unwanted materials; the fouling greatly impedes effectiveness, resulting in tremendous financial and environmental costs. Currently no on-line cleaning solution exists for situations involving hot, chemically reactive fluids. The EU-funded CLEANEX (A method for on-line cleaning of heat exchangers to significantly increase energy efficiency in the oil, gas, power & chemical process sectors) project undertook to develop the necessary process. Rather than cleaning the tubes after build-up has occurred, the new method suppresses fouling and maintains the tubes in a clean condition through projectiles that constantly circulate through the system. Work consisted of three phases. The first focused on gaining knowledge necessary to validate the concept. Phase two saw considerable development and testing of all enabling technologies, plus the integrated prototype. The method involved constantly passing projectiles through hot heat-exchanger tubes, wiping them clean before build-up can occur. The project published a total of 11 technical findings, meaning effectively that the proposal worked as intended. The final phase included preparations for protecting and marketing the developments. The group patented particular technologies – projectiles and the injection system for the projectiles into the tubes – to ensure removal of hydrocarbon build-up in heat-exchangers. CLEANEX deliverables mean increase in efficiency in the heat exchanger, improved output and decrease in maintenance times. The initiative represented substantial market potential, plus opportunity to significantly reduce carbon-dioxide pollution.