Comparing repair inspection methods

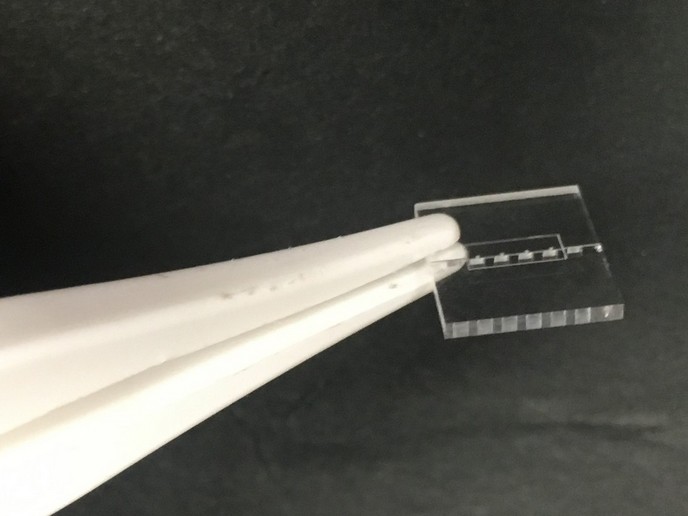

Adhesively bonded composite repairs of defects are superior to mechanically fastened ones in many ways, yet they are very sensitive to process parameter variations. Such subtle fluctuations can subsequently result in flawed repairs that negatively impacts safety and highlights the need for effective non-destructive testing (NDT) procedures. EU-funded scientists working on the project 'Comparative evaluation of NDT techniques for high-quality bonded composite repairs' (COMPARE) studied different technologies. They compared conventional ultrasound (both immersion automated conventional ultrasound (ACU) and manual conventional ultrasound (MCU)), piezoelectric ultrasound (PZ UT), laser shearography (LS) and laser ultrasound (LUT). All techniques satisfactorily located defects. Their differences in other areas such as resolution, speed and sensitivity could point the way to specific applications depending on requirements. For example, LUT and ACU provided the highest feature resolution and could detect flaws of any size that do not meet aerospace safety standards. LUT had the highest resolution of all, besides being non-contact and non-invasive unlike ACU. However, LUT requires the highest safety measures, including eye protection and a special shielding around the inspection zone. Moreover, the highest level of operator expertise together with LS is also needed. Both ACU and MCU were able to indicate depth features. Inspection speeds were highest for LS but the resolution was the lowest among all systems tested. However, feature depth information could be extracted from LUT data with subsequent signal processing and analysis. This suggests that LS could be used as a rough detection system followed by LUT or ACU when a defect is found. Ensuring the reliability of adhesively bonded patches will encourage their widespread use and enhance flight safety while decreasing maintenance and operational costs. COMPARE provided valuable information about the pros and cons of various NDT technologies in assessing the integrity of adhesively bonded composite repairs. Enhanced safety at a lower cost is certain to positively impact on the competitiveness of the EU aerospace industry.