Clean water from industrial waste

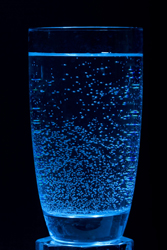

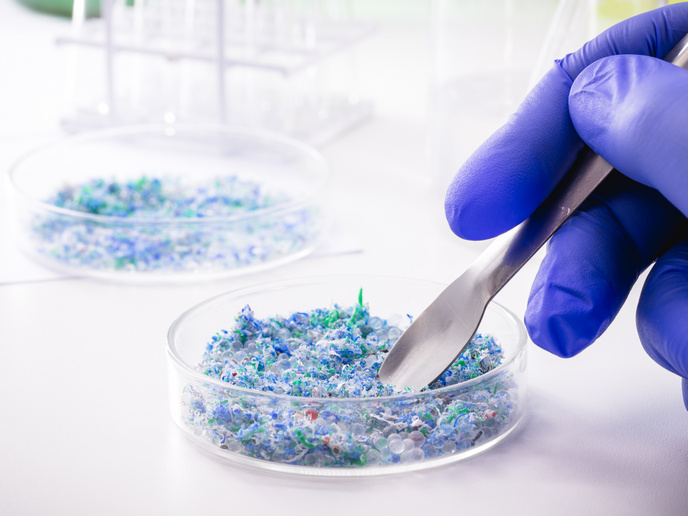

Funded by the EU, the PROMETHEUS(opens in new window) project designed a system that uses a membrane to separate toxic chemical agents from wastewater. The membrane filtration is then followed by an evaporation cycle to purify the water. This approach would reduce environmental pollution, waste disposal volumes and energy costs. Project activities mainly focused on the selection of suitable membranes, fouling prevention, and the selection and design of the evaporator. The resulting system was developed and tested in a semi-industrial pilot plant in Spain, where it successfully fulfilled the target requirements. Researchers found that the membrane could be operated continuously for over 24 hours and that it provided an energy saving of up to 55 %. The treatment system also allowed for an overall water recovery of up to 99 %. This positive result means that industries would be able to meet European directives regarding water reuse and cleaning. It also allows manufacturers to convert wastewater into valuable by-products. Taken together, these findings indicate that PROMETHEUS addressed a critical economic, environmental and legislative problem within rubber and aluminium industries, which will promote competitiveness going forward.