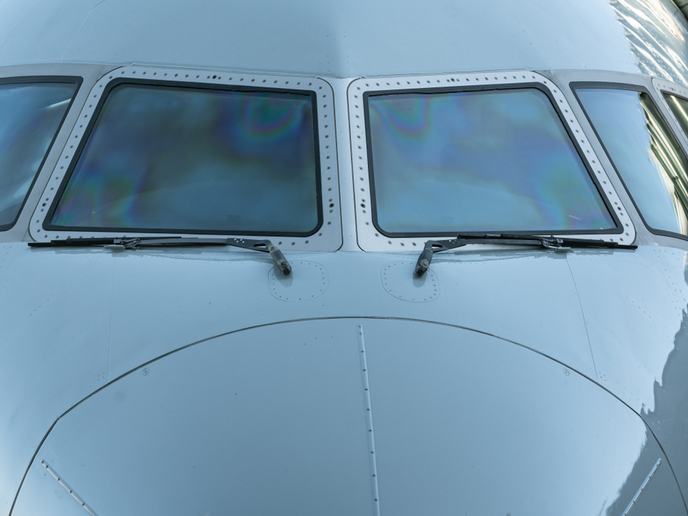

An eco-efficient solution for sustainable aviation

The advanced aluminium-magnesium-lithium alloy targeted for use as aircraft fuselage skin has more than 10 % lower density compared to conventional aluminium alloys. This new product is expected to offer further weight savings through design re-optimisation. In addition, its physical and mechanical properties allow for reduced fuselage wall thickness, higher durability of the aerostructure and the employment of eco-friendly surface treatments. With the financial support of the EU, researchers have taken the alloy from a readiness level of three to that of six. The first step of the EU-funded project ECEFA (Eco-efficient aluminium for aircraft) was to roll and heat treat an existing slab and subject it to extensive testing. The test campaign included corrosion, fatigue and damage tolerance tests to understand better its potential to meet airframers' requirements. Two different thicknesses of 2.1 and 4.5 mm were tested. Based on the results, which confirmed the ability of the aluminium, magnesium and lithium alloy to satisfy mechanical and toughness requirements, sheets with a slightly modified composition were cast. Additional tests helped to define surface process parameters to enhance surface protection and corrosion resistance. The improved corrosion resistance allowed elimination of the use of chromium – a hazardous material whose usage must be phased out in order to meet increasingly stringent environmental legislation. The ECEFA project has resulted in a step change in the eco-efficiency of airframes. Decreasing the weight of the fuselage and maintenance operations while enhancing performance will ensure that the environmental impact is kept to a minimum and also provide an important boost to the industry's competitiveness.