Real-time multi-spectroscopic data fuels a revolution in pharma process control

Conventional batch manufacturing of pharmaceuticals has been the norm for more than half a century. A lengthy, sequential, multi-step process, it generally relies on offline testing and significant downtime. Continuous manufacturing, already used by chemicals and petrochemicals industries, is gaining ground in the pharmaceutical sector thanks to technological advances and regulatory support. The EU-funded IMPAX(opens in new window) project has developed a novel inline multi-spectroscopy device for continuous manufacturing that will simplify and accelerate process development, provide enhanced quality control, reduce waste and increase efficiency.

Supporting a revolution

Process analytical technology(opens in new window) or PAT refers to the suite of tools that enables data acquisition and analysis, process control, as well as knowledge management. These tools will play an integral role in pharma quality control for Industry 4.0 the transition to smart and autonomous systems fuelled by data and machine learning that is often referred to as the fourth industrial revolution. Pharma industry 4.0 PAT is expected to increase productivity by 30-40 %, decrease quality control costs more than 50 %, and reduce manufacturing deviations by 65 %(opens in new window). German SME ColVisTec AG, Berlin(opens in new window) is leading the pack in PAT technology.

Three ‘eyes’ are better than one

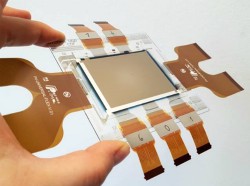

For the last decade, ColVisTec has been supporting inline process monitoring for the world's leading manufacturers in the paint, plastics, pharmaceutical, and chemicals industries. With IMPAX, the company created the first production monitoring platform that uses three spectroscopy types simultaneously. Near-infrared spectroscopy(opens in new window) (NIR) and Raman spectroscopy(opens in new window) are added to its existing unique ultraviolet-visible spectroscopy(opens in new window) (UV-Vis) platform. Project coordinator Jan Johnsen, CEO of ColVisTec AG, Berlin(opens in new window), explains: “The three techniques are complementary. UV-Vis is extremely sensitive and quantitative, but not always specific – for example, it cannot differentiate between materials with the same colour. Raman spectroscopy is highly specific but not always quantitative. NIR fills the gap, quantifying ratiometric changes (changes in relative quantities of materials) and water content, something that cannot be easily achieved with UV-Vis.” Combining all three provides a much richer picture of what is happening in the process at any given time.

Benefits for industry extend to patients

IMPAX’s multispectroscopy device, GiANT, will have numerous benefits for the pharmaceutical sector and for patients, fully supporting real-time release testing(opens in new window). Continuous collection and analysis of process data means deviations can be detected and potentially automatically remedied quickly. Johnsen summarises: “Our novel multi-spectroscopy system is designed to improve the efficiency and quality of pharmaceuticals, potentially reducing manufacturing costs and waste. We hope our system will also be used in earlier stages of formulation and process development to accelerate drug discovery and get new medicines to market sooner.”

A continuous flow of products to market

Although not originally planned, a new optical probe enabling simultaneous NIR and UV-Vis spectroscopy from a single probe head emerged from the work and is already commercially available. As for GiANT, ColVisTec has prepared a commercialisation plan for its launch. It will be introduced at pharma and extrusion conferences and events throughout 2020. ColVisTec is already working with selected pharma partners and is actively seeking collaborations. No doubt GiANT will play an important role in the gargantuan global response to current challenges.