Micro-sampling device to revolutionise blood collection

In Europe, tens of millions of blood tests are performed annually, often as part of regular check-ups to diagnose certain abnormal values, such as low haemoglobin(opens in new window) or high/low sodium or potassium levels. Most routine laboratory tests are performed on plasma(opens in new window), a liquid component of blood which contains dissolved proteins, glucose, clotting factors, mineral ions and hormones. Preparing blood plasma remains a time-consuming and costly process. In fact, while blood analysis remains one of the most powerful medical diagnostic tools, collection techniques have changed little since the 1950s. “The procedure is very invasive, requiring the insertion of a hollow needle in a vein,” says HemaXis DX(opens in new window) project manager David Forchelet, R&D Manager at DBS System(opens in new window) in Switzerland. “Blood quality can quickly degrade, and if samples need to travel long distances, the logistical costs can be very high.”

Quick, accurate sampling

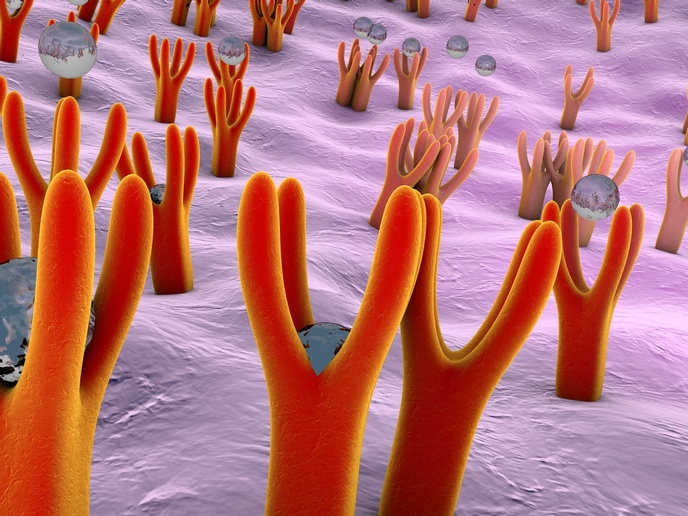

To address these challenges, DBS System has developed a plasma spot device that uses microfluidics technology(opens in new window) to collect and prepare accurate volumes of controlled samples of plasma. From a pinprick of blood, the HemaXis DX chip separates plasma from whole blood without centrifugation(opens in new window), filtration or pumping. The technique requires 100 times less plasma than traditional methods of drawing blood. “The plasma is immediately ready to be analysed in the lab, as sample preparation occurs in the device directly at the point of collection,” explains Forchelet. “This allows clinicians to collect the required drops of blood from the fingertip in a minimally invasive, fast and painless manner.” EU funding was used to support DBS System in preparing the innovation for market. “A key challenge for any product – but perhaps especially for medical devices – is to identify where and how your impact can by maximised,” says Forchelet. “This is because regulatory flexibility is relatively low. It is therefore important to be cautious, and to test your devices with early adopters as much as possible.” A 3-month feasibility study was carried out to determine the technical and economic viability of the HemaXis DX device. The company reviewed its supply chain and identified key stakeholders needed to be involved for successful commercialisation.

Bringing innovations to market

A global competitive analysis carried out through the HemaXis DX project confirmed that DBS will be the first company to commercialise a microfluidic technology-based device that passively separates plasma from blood. Two hospitals have already expressed an interest in working on the clinical validation of the device. The company is now looking to bring the innovation to market. “The ultimate objective for DBS is to launch the HemaXis DX device on the market by 2023,” says Forchelet. “This EU SME Instrument grant enabled us to review in more detail the current stage of development, and to define a plan based on the remaining activities required for commercialisation.” This plan includes a number of key technical and strategic activities including scaling up production of HemaXis DX devices and performing clinical studies. These activities are foreseen within the grant component of a forthcoming EU-funded accelerator project. “We were founded with the aim of making the blood collection process less invasive and traumatic,” says Forchelet. “The company’s belief is that micro-sampling will be the future of blood sampling, improving both the patient experience and the overall analytical workflow.”