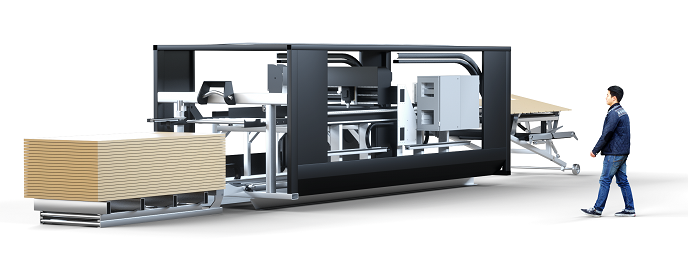

Robot assistants for increased productivity

The worlds of electric vehicles (EVs) and robots are starting to overlap. As demand for greener, more customised and better quality vehicles is ever growing, efficiency of production and precision of the production line machine need to be increased. Researchers and scientists on the 'Toolkit for building low cost robot co-workers in assembly lines' (LOCOBOT)(opens in new window) project are developing a toolkit for low-cost and flexible robotic assistants to lend a helping hand where needed along the car assembly line. The project's low-cost robotic co-worker includes the robot itself, along with plug-and-produce modules, and an engineering toolkit required for quickly configuring the robot and programming it for specific tasks. Kinematic modules will be built upon a mobile platform. The single modules should be lightweight and compliant to enable safe cooperation with humans, as well as standardised to allow the configuration of different kinematic structures. Challenges that the LOCOBOT team needs to overcome are the time-consuming and costly reprogramming and set-up of control algorithms and software. For this reason, the control algorithms need to be adaptive and self-optimising to account for different kinematic structures, deal with vibrations caused by the mobile platform and achieve precise positioning despite the compliant modules. Robots will also be equipped with a stereo camera system and audio components to acquire and process audiovisual information. This will be required for the robot to learn and cooperate with human workers. Team members have already developed the human–robot interaction and technical requirements, considering three different scenarios in the car assembly line.These 'near-to-production' scenarios concerned starter pre-sorting, battery pre-picking and battery mounting. In these demonstrators, the robots relieve human workers from most of the manual work. Intensive evaluation of human–machine interaction was carried out in several validation tests. The shift to EVs is a unique opportunity for the EU to establish strong leadership in the industry. Thanks to greater flexibility and efficiency, within 2 to 5 years LOCOBOT technology could generate EUR 150 million in savings. This will be even greater in the ensuing years, depending on how production numbers of the EV turn out.