Newer, faster way for cleaning up oil slicks

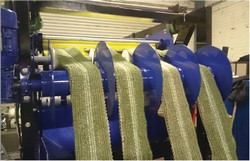

Oil spills can cause considerable damage to the marine environment by poisoning and smothering ocean life. Although a wide range of technologies currently exists for the removal of oil spilled into water, none are capable of successfully recovering spilled oil from cold, rough seas. The in situ burning of the spilled oil and the use of dispersants are of limited value and must be implemented within 72 hours of the incident. However, these methods do not remove all the oil, even under ideal conditions. Containment and collection of the oil is a common solution, but requires calm seas for it to be effective. This challenge was addressed by the FORCE7(opens in new window) (High performance oil spill recovery system suitable to effectively operate in rough sea waters based on improved oleophilic/hydrophobic materials) project. Members of the consortium developed and tested a highly effective oil recovery system capable of operating under difficult conditions that comprised interconnected mops. These were then deployed behind a tugboat and dragged through an oil slick. The mops were made up of novel combinations of natural and man-made fibres that absorbed quantities of oil, but not water. Once they are saturated, the mops are brought onboard and squeezed by rollers to remove the oil, which is collected. They are then redeployed for another cleaning cycle. Project partners developed and tested fibres to determine their oil sorption capacity and their ability to repel water under different conditions. The information was used to select the most suitable grades of synthetic and natural yarns. Currently, polypropylene is the most commonly used absorbent material for clearing up oil spills. However, natural fibres such as cotton, wool or flax show superior behaviour and come from renewable resources. Researchers also investigated the best surface modification treatments in order to improve the fibres' properties by developing high-performance textile structures. The materials were then tested on a small scale under simulated working conditions to determine mop behaviour, showing outstanding oil recovery efficiency (oil/water ratio up to 95 %). FORCE7’s main advantage is that it can be manoeuvred at 5 knots, which is five times faster than traditional booms. By turning more rapidly and travelling faster up and down the oil slick the amount of oil encountered in a given time can be maximised. It is considered that a vessel operating 18 hours a day, every day for a year could recover 65 million litres of oil (more than 410 thousand barrels).