Automatic smoothing for laminar flow

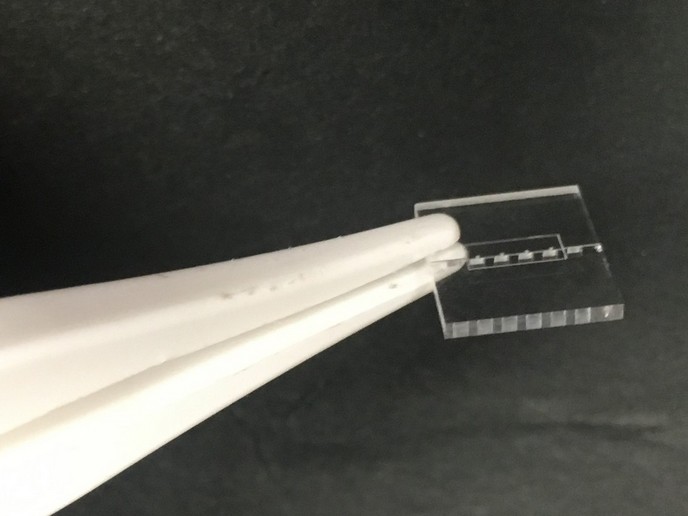

Europe's aerospace industry is a pillar of its economy, generating EUR 220 billion and providing 4.5 million jobs. In addition, aerospace technologies are catalysts for innovation, generating spill-over effects in other sectors of the economy. However, the aerospace industry is entering a new era of competition from rivals in Brazil, Canada, China, India and Russia and even the Middle East and Asia, in addition to its traditional competitor the United States. Competing with these countries on the basis of costs is impossible, so the EU seeks the technological advantage underpinned by targets of sustainability and low environmental impact. The EU funded the project 'Development of a rapid, multifunction, automated gap filler device' (NOGAP)(opens in new window) to create a multifunctional robot to solve the problem. Integrating a computer vision system and 2D laser measurement device, the seven-axis robot can independently detect and analyse the size of gaps on the wing surface. It then applies the necessary sealant that it projects onto the surface via an innovative filler injection system with a smart nozzle, for which a patent has been filed. The sealant solidifies upon contact with air and the robot cures the sealant if necessary. Post-application metrology control then examines the surface to verify that is has been properly finished. The robot was presented at a variety of aerospace events, including the Internationale Luft- und Raumfahrtausstellung (ILA) Berlin Air Show and Eurosatory, the world's largest international land and air defence and security exhibition. NOGAP has delivered the first automated gap filler for aircraft manufacturing that is capable of meeting stringent surface smoothness requirements required for NLF. It eliminates manual procedures, enhancing quality and reducing time and rework, making a significant contribution to the Clean Sky programme's NLF wing development. On a broader scale, the robotic filler should find its place comfortably in the aeronautical smart factories of the future.