All-electric vehicle bodies made of steel without moulds and dies

Electric mobility is driving research and innovation, largely centred on batteries and electric powertrains, whose cost is dropping. A main concern of original equipment manufacturers is now the cost, both initial and operating, of producing a safe electric vehicle body. The EU-funded AVANGARD(opens in new window) project has delivered a comprehensive solution, a flexible manufacturing environment based on rapid and seamless reconfiguration of machinery and robots. Its automotive body, built with about 10 % of the usual investment, will pave the way to affordable urban fully electric vehicles.

Dies are industry standard for cold and hot forming

Historically, automotive vehicle body components have been produced via metal stamping of steel in which a die is pressed into sheet metal to form the desired shape. Recently, a disruptive technology called giga casting(opens in new window) is taking the automotive and robotics worlds by storm. Giga casting can produce die-cast aluminium parts of unprecedented sizes from molten metal, combining many components into one; this eliminates many machines and welding robots and requires less than half the time of steel metal stamping. However, meeting the rapidly changing needs of a growing electric mobility market that will include cars, trucks, bikes, and more, will require a shift from mould-based, die-casting processes to more flexible production lines.

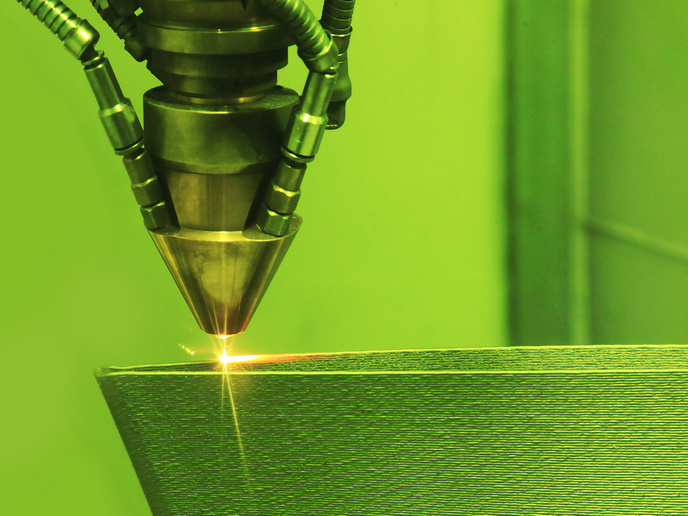

Laser cutting replaces die-casting and metal stamping

According to project coordinator Pietro Perlo of I-FEVS(opens in new window), “AVANGARD has demonstrated the manufacture of more than 80 % of the vehicle body’s building blocks via laser cutting followed by punching-bending and welding, minimising the construction of expensive dies and time-consuming design and test procedures.” The scalable platform requires a small capital expenditure and demonstrates a short return on investment for low production volumes and significant profit for large production volumes. It requires very few changes at minimal cost to produce passenger cars, trucks and vans with lightweight body frames and exterior panels made of 100 % recyclable steel. Further, it enables a radical reduction in energy consumption and CO2 emissions. Finally, the components meet EU safety regulations and the European New Car Assessment Programme(opens in new window) safety standards.

Flexible electric vehicle manufacturing technology

“The potential of the platform and its robotised pilot line goes well beyond the e-vehicle demonstrators developed. For example, Europeans bought 23 million bikes and e-bikes in 2021, the majority of whose frames were made in Asia. Our platform manufactured bike and e-bike frames at a cost lower than that of the least expensive Chinese manufacturers,” Perlo notes. AVANGARD’s cloud-based environment and hybrid public-private blockchain increases security and data processing speed while storing sensitive data at partner facilities. It will also enable future electric vehicles to be produced with a QR code whose scan will supply information about processes, energy, emissions, tests and materials associated with manufacturing. This will be equally beneficial to potential customers and entities recycling critical raw materials. Partner I-FEVS has now established a collaboration with the world’s largest steel producer. Perlo concludes: “The achievements are supported by a cluster of projects, including Multi-Moby, highlighting perseverance, teamwork and the value of EU funding. Thanks to our radical simplification of manufacturing, we have demonstrated that safe, affordable, sustainable and high-performing all-electric vehicles can be manufactured at a very competitive cost here in the EU.”