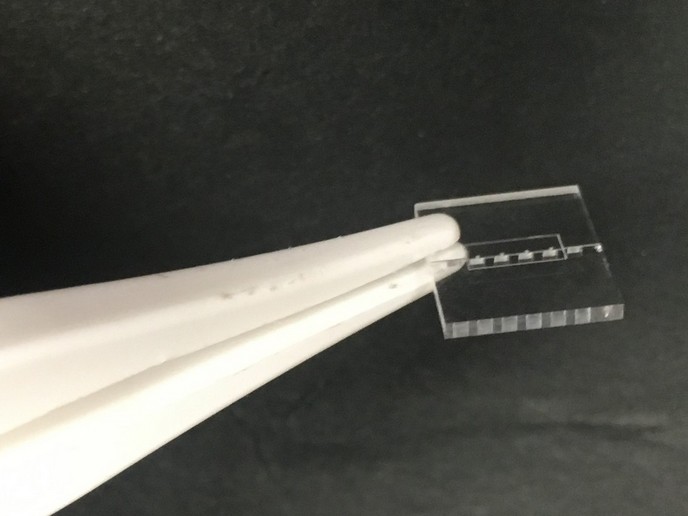

Laser optics detect rail damage

Recently there has been an increased interest in controlling the quality of railway tracks by all rail transport companies, due to the increase of merchandise transported by trains and the increase in railway speed due to the promotion of high-speed projects. In addition, the increase of rail traffic and the use of trains by more and more people enhances the need for better safety standards. Frequent maintenance ensures that railways, tramways and subways are in the best possible condition. To support this effort and at the same time cut down on the necessary costs, a consortium of Small and Medium Enterprises (SME's) has developed a laser optics system that by using the principle of optic triangulation through laser beam and a high resolution camera, measures in real time the whole rail profile. The system can be installed on every kind of train and, therefore, dispenses with the need to use special trains for inspection, as was the practice until now. Moreover, additional traffic congestion is avoided since the railway network can now be inspected any hour of the day by the scheduled railway vehicles. A prototype of this novel measurement device was implemented and successfully tested in railways, tramways and subways and field tests have clearly demonstrated that it is capable of high precision measurements, without the latter being influenced by external conditions, such as surface rail conditions, ambient light conditions or even vibrations. Conventional train carriages with the proposed system installed will provide the profile of either flange rails used in railways and subways, or grooved rails that are used in tram transport. Railway companies will benefit greatly from such a non-intrusive, on-line measuring system, since it will allow them to analyse accurately the state of the tracks and, consequently, plan the necessary maintenance activities. Not only are costs decreased, as maintenance now takes place only when needed and not at regular time intervals, but more importantly there is an increase in transport safety and a reduction of acoustic pollution. At a workshop that will take place in November of 2001 the consortium of SME's will present to the railway companies, not only the proposed technology, but also the know-how acquired that may provide the basis for development of other railway systems solutions.