New technology streamlines composite repair

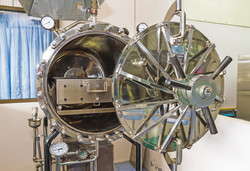

Aerospace manufacturers are increasingly turning to OOA systems to cure composite parts mainly because they are cheaper to buy and operate compared to traditional autoclave systems. So far, they have been widely using resistance heating blankets to conduct heat to the repair area by using one or two spots for temperature measurement. Although this method provides good results for small repairs, large temperature discrepancies – cold and hot spots – are frequently observed when larger areas need to be heated. Scientists extended the heating blanket technology to perform high-quality, efficient and cost-effective OOA repair curing of large aircraft parts within the framework of the project ADVANCED (Advanced heating system and control mode for homogeneous high temperature curing of large composite repairs). This OOA innovative technology allows large aerospace parts to be repaired with high quality while achieving significantly less energy consumption. To ensure even heat transfer, scientists applied multi-zone closed-loop control and customised variable heating elements adapted to the thermal signature of the repaired part. Tailoring the heating element performance to the part geometry eliminates the need for defining parameters (for example, because of dissimilar heat losses), thus increasing reliability of the repair process. The successfully developed heating device prototype reduces the repair time and is more eco-friendly given that it produces minimum material waste and consumes less energy. ADVANCED's green repair solution is in line with the Clean Sky objectives, ensuring safe and 'ecolonomic' long-term use of an aircraft structure. The proposed repair process should improve reliability and performance, and also minimise the time an aircraft needs to spend on the ground for repair. Successful deployment of this technology will put the EU aerospace manufacturing sector firmly in the global lead.