Membrane processes for treating polluted water

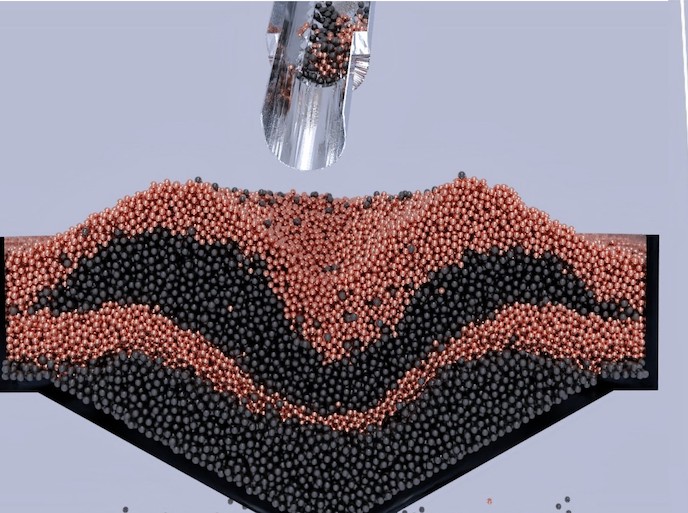

Membrane water-treatment facilities may offer the opportunity of exploiting currently untreatable water recourses. The use of membranes is very efficient for desalination and purification of water. Moreover membrane processes have a potential for great energy savings and substantially reduced costs compared to thermal desalination plants. Unfortunately, until now the use of membranes was limited and applied only to certain water sources due to the problem of membrane fouling. Membrane fouling in simple terms is the clogging of the membrane from the polluting agents. Fouling therefore immediately requires cleaning the membrane or even at times, replacing it. The current project has focused its research efforts on ways to minimise fouling and protect the membrane from rapid degradation. Succeeding in such an aim immediately upgrades the use of water treatment facilities. The research objectives were achieved with the development of various innovative methods. New advanced feed pre-treatment facilities were explored based on the use of an ultrafiltration membrane. The fouling control techniques were improved with the aid of new anti-scalants. Anti-scalants are materials that basically have the ability to clean up the membrane from fouling. Finally, criteria for the selection of the optimal pre-treatment facilities depending upon the type of raw material and membrane were developed. There are four main membrane processes currently used; Microfiltration (MF), Ultrafiltration (UF), Nanofiltration (NF) and Reverse-Osmosis (RO). From pilot tests the criteria for the design and operation of membrane processes for high fouling water were developed. Especially for problematic water sources like polluted rivers and brackish waters, optimisation of the design results in some cost reduction but also at very low energy consumption. For more details on the criteria for selection and design of membrane processes click here(odnośnik otworzy się w nowym oknie). For the Reverse-Osmosis desalination process there are three categories of fouling, namely the colloidal or organic fouling, bio-fouling and scaling. Experimental results covering a wide range of important parameters in membrane colloidal fouling have been obtained. Moreover a comprehensive literature survey and critical evaluation of the literature on colloidal fouling has been performed. For more information on the improvement of the fouling indices for RO feed waters click here(odnośnik otworzy się w nowym oknie). Additionally project partners have also developed a special test section that allows on line optical microscopic observations to be performed during membrane filtration or back-washing. The optical observations provide valuable information about the development of fouling deposits. For more details on the test section click here(odnośnik otworzy się w nowym oknie). The current research project has substantially improved the cost and energy efficiency of water purification processes. Better selection of anti-scalants, novel fouling mitigation measures and the increased productivity and lifetime of RO membranes due to better pre-treatment water quality, will greatly benefit water industries and communities. Industrial sectors like agriculture and food industries, the desalination industry, water treatment companies and anti-scalant manufacturers will extensively use the developed technologies.