Investigating surface thermochemical treatments

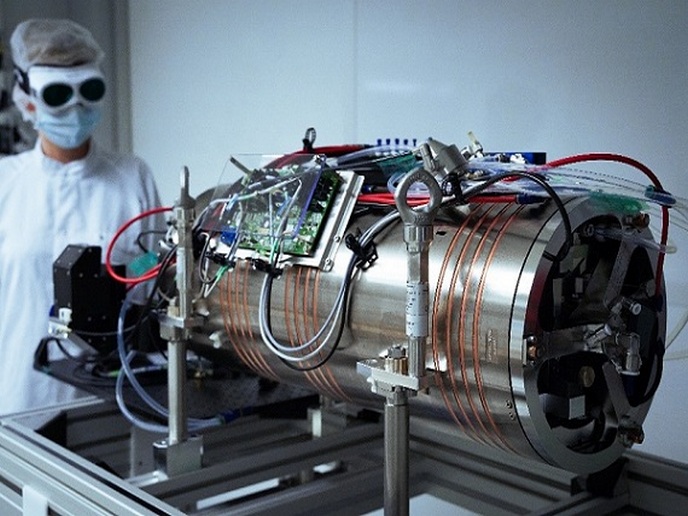

Thermochemical methods for surface treatment have been recently introduced for metallurgical alterations of the structure and properties of components. The component can potentially display enhanced stress resistance, required hardness properties or even modifiable composition. Employing the versatile, environmentally friendly and cost-effective plasma technology in surface thermochemical treatment could improve both the process efficiency and the product's reliability. The addition of rare elements in these techniques has great potentials for the technology's further improvement though these have not been proven until now. For this purpose, this four years project studied a family of three plasma thermochemical surface treatment technologies. These included DC plasma nitriding (DCPN), active screen plasma nitriding (ASPN), and Plasma Immersion Ion Implantation (PI3) nitriding. The investigations led to a set of significant results for breakthrough developments in the field of industrial plasma thermochemical processing. On the grounds of the given unique detailed evaluation of the complex ASPN technology, the latter has been widely accepted by contemporary industrial community. Similarly, Optical Emission Spectrometry (OES) has been potentially established as the most accurate non-destructive quality control technique for the powerful PI3 nitriding technology. The project work could lead to more durable and reliable products with safe, environmentally friendly and cost-effective processes. Particularly for the steel industries, the plasma nitriding methods could substantially contribute to great energy savings and enhanced efficiency. As surface engineering is becoming an ever more decisive factor in design and marketing, these outcomes could be employed for viable solutions to challenging industrial problems.