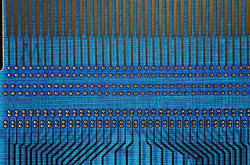

Controlling next generation microprocessors

Lithography is the technique whereby microcircuits are etched into silicon wafers; often using photographic methods to imprint the circuit pattern. Miniaturising the circuits, and their components, means improving the resolution of such photolithography processes, and this is dependent on the wavelength of light used. The International Technology Roadmap for Semiconductors (ITRS) has defined a series of "technology nodes" as milestones in the trend towards greater miniaturisation based on a decreasing "critical dimension" (CD) of features of the circuit's components. In microprocessors, for example, the gate length of the transistors is a critical dimension related to the processor's speed. The "Usable vacuum ultra violet lithography" (UV2Litho) project investigated four metrology techniques that address the measurement and process control needs of manufacturing techniques for a critical dimension of 65nm. The project evaluated four methods - scanning electron microscopy (CD-SEM), CD-scatterometry, atomic force microscopy (CD-AFM) and combined techniques. These evaluations were based on five criteria; on-time availability, ultimate resolution, precision, interaction with the measured structure and universality. Each technique was compared to the ITRS roadmap as a benchmark, while efforts were made to investigate innovative methods, and identify weaknesses for the newest of these technologies. The project found that tool-to-tool matching – the need to ensure that measurements are consistent among different metrology tools in different fabrication plants - was the critical factor. The team found that none of the metrology techniques evaluated were able to meet the tool matching requirements of 65nm technologies. In the initial stages of development for the 65nm node, however, a single tool could be used for low-volume measuring of silicon wafers at ultimate resolution and precision. Commercially available tools are already close to the performances needed. The project is looking for semiconductor equipment manufacturers who would be interested in commercialising its findings, and recommended procedures, on tool-to-tool matching. The results are likely to assist metrology tool selection and include conclusions on matching tools using different technologies, such as combined focused ion beam and scanning electron microscopy (FIB+SEM) with CD-AFM and CD-scatterometry. The team is also looking for semiconductor companies or consortia to collaborate on further development towards the "45nm technology node". The results are also relevant to 65nm technologies that use methods other than photolithography at wavelengths of 157nm.